CNC Turning- and Milling Center

Machinelist: CNC Turning- and Milling Center

CNC Turning- and Milling Center

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20313 · CNC Turning- and Milling Center

MAZAK - Integrex i-100S - - 2013 - Mazatrol Matrix 2

Technical details

5-axis simultaneous machining - CNC control Mazatrol Matrix 2 - Main & counter spindle - 6" chuck (B206) - Tool changer (36-fold) HSK - Coolant system - Chip tray

Datasheet

Request / Contact

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03871 · CNC Turning- and Milling Center

DOOSAN DAEWOO - PUMA TT 1500 Y - - 2012 - FANUC 18 iTB

Technical details

PUMA 2500 LSY - Control Fanuc 18i TB - Spindle bore 65 - SPINDEL 1 COLLET CHUCK - The machine has 470 mm turn length - Bal screw instead of Rack and Pineon 2 X turret WITH 12 POSITION - Swarf conveyor - Interface for bar Feed - Automatic tool measuring - High preassure coolant pump 7 bar IEMCA BAR FEEDER

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-17959 · CNC Turning- and Milling Center

MORI SEIKI - NTX1000 - - 2012 - MSX-711-IV Mori Seiki

Technical details

MAPPS control system Renishaw HPRA (manual tool presetter) Blum Laser Control Direct measuring system X;Y;Z;B Collet chuck SMW Autoblok KSZ-MB-040-Z140 Workpiece conveyor belt Bar feeder Breuning Irco ILS-RBK-10012 Knoll band filter KF10/500 / IKZ with milling spindle 7 stages up to 70 bar Chip conveyor ConSep 2000

Datasheet

Request / Contact

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03941 · CNC Turning- and Milling Center

DOOSAN daewoo - PUMA 2100 lm - - 2012 - FANUC

Technical details

PUMA 2100 LM - Control FANUC - Spindle bore 76 - SPINDEL 1 CHUCK 25 MM 18.5 KW 4500 RPM - The machine has 1830 mm turn length - Bal screw instead of Rack and Pineon turret has 12 POSITION Swarf conveyor - High preassure coolant pump 7 bar STAEDY DIA 20-180 MM

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03967 · CNC Turning- and Milling Center

CMZ - TL 25 Y - - 2012 - FANUC 31 A

Technical details

4 AXIS CNC LATHE WHIT Y AXIS LIVE TOOLS 1 disc turret with 12 position, , cylinder shaft, 1 tailstock, , hydr. clamping CONTROL FANUC 31I A

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03948 · CNC Turning- and Milling Center

MAZAK - Quick Turn Smart 350 - - 2012 - MAZATROL SMART Dialog

Technical details

Machine IN GOOD CONDITION SOME tool holDER INCLUD WITH STEADY AND CHIP CONVOYER

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

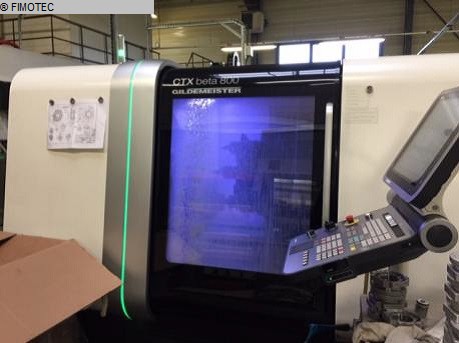

#1022-2323 · CNC Turning- and Milling Center

GILDEMEISTER - CTX Beta 800 - - 2012 - Siemens 840 D

Technical details

CNC turning and milling center in good condition with driven tools, C and Y axis, subspindle and CNC control Siemens 840 D. Operating hours according to the attached photo from February 8, 2024 The hours may increase as the machine is currently still in use. Max. workpiece diameter 410 mm Max. workpiece length 800 mm Max. travel X-axis 300 mm Max. travel Y-axis +/- 50 mm Max. travel Z-axis 850 mm Turning diameter over cross slide 250 mm Main spindle drive power 65 kW Spindle bore 75 mm Spindle speed of the main spindle 4000 rpm. Spindle speed of the counter spindle 5000 rpm. Equipment and accessories: Chip conveyor Coolant system with paper belt filter Oil mist extraction system Electrical control cabinet with air conditioning (tropical package) 3-jaw power chuck on main and subspindle Basic equipment of tool holders Documentation/Manual

- Marcels Maschinen AG

- Anthoptstrasse 11

- 8222 Beringen (Schaffhausen)

- Schweiz

-

(0041) 44 872 3400

(0041) 44 872 3403 -

info@marcels-maschinen.ch

http://www.marcels-maschinen.ch

#1065-5000 · CNC Turning- and Milling Center

YCM - GT 300 MB - - 2011/08 - FANUC TXP-200 FA

Technical details

Datasheet

Request / Contact

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02910 · CNC Turning- and Milling Center

BENZINGER - DoLittle B3 - - 2011 - Sinumerik 828 D

Technical details

Turn-mill centre for maximum precision Benzinger DoLittle B3, built in 2011 - Dolittle B3 main and counter spindle with linear tool structure Tool stations: Main spindle 10 tools + 1 stop (2 blocks 5 tools each + 1 stop) Counter spindle 11 tools (2 blocks of 5 and 6 tools) Driven tools via the swivelling axis 6 tools Machine ON/OFF: 1 shift There are 10 tool blocks in total. Technical data - Traverse path X1 axis 320mm - Traverse path Z1 axis 145mm - Traverse path Z2 axis 90mm - Traverse path Y-axis 80mm - 2x C-axis - Rapid traverse speeds X/Y/Z 30 m/min - Water-cooled motor spindle 16 mm, 15,000 1/min - BENZINGER linear tool carrier system - Swivelling NC axis with 6 driven tools Accessories: Knoll high-pressure pump Hydra cooling system Suction channel Tool holder, collets 10 tool blocks

- STEINHAND GmbH

- Am Stahlwerk 15

- 45527 Hattingen

- Deutschland

-

+49 (0) 2324 / 977 26 - 01

+49 (0) 2324 / 977 26 - 99 -

info@steinhand.de

www.steinhand.de

#2026-1044 · CNC Turning- and Milling Center

INDEX - G400 S-1/300 - - 2011 - INDEX - C200-4D

Technical details

CNC Turning- and Milling Center | INDEX - G400 S-1/300 The machine is in a very good condition with only 2500 H main working hours. + MARPOSS probe The machine is in a well-maintained condition. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - #Tags: G400 | G 400 | G400 S1 300 | G400S1 300

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9064 · CNC Turning- and Milling Center

MORI SEIKI - NLX 2500 SY / 1250 - - 2011 - M 730 BM MAPPS IV

Technical details

CNC - Turning- and MillingCenter DMG MORI SEIKI - NLX 2500 SY / 1250 - Subspindle - only 9.600 Spindle hours (May 2023)

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9114 · CNC Turning- and Milling Center

MORI SEIKI - NZ 2000 T3 Y3 - - 2011 - MSX 701 IV / MAPPS IV

Technical details

CNC - Turning- and MillingCenter MORI SEIKI - NZ 2000 T3 Y3 - Main- and Subspindle - 3 turrets, 2 upper, 1 below - 3 Y-Axis - 3x 16 driven tool stations - extensive accessory package

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03952 · CNC Turning- and Milling Center

MORI SEIKI - DURA TURN 310 ECO - - 2010 - MSX 853 MITSUBISHI MIT M

Technical details

NICE MACHINE with MSX 853 IV MAPPS - Programming - driven tools - tail stock - coolant equipment CHIP CONVEYOR

- STEINHAND GmbH

- Am Stahlwerk 15

- 45527 Hattingen

- Deutschland

-

+49 (0) 2324 / 977 26 - 01

+49 (0) 2324 / 977 26 - 99 -

info@steinhand.de

www.steinhand.de

#2026-1538 · CNC Turning- and Milling Center

DOOSAN - PUMA MX 2100 ST - - 2010 - FANUC 31i-B

Technical details

CNC Turning- and Milling Center | DOOSAN - PUMA MX 2100 ST equipped with chip conveyor. Additional equipment: + counter spindle + B axis The machine is in good condition. A machine video from the production plant will be shared on request. Please refer to further technical details in the attachement of the offer. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - #Tags: MX2100ST | MX-2100 ST | MX 2100ST | MX2100 ST

- MAMACH Machinenhandel BV

- Campagneweg 10

- 4761 RM Zevenbergen

- Niederlande

-

+31 (0)168325354

-

info@mamach.nl

www.mamach.nl

#2041-2794 · CNC Turning- and Milling Center

MAZAK - Integrex E 500H-II x 3000 - - 2010 - Mazatrol Matrix

Technical details

- Klaus Rosenboom GmbH

- Oppenheimer Str. 19

- 28307 Bremen

-

+49 (0) 4 21 / 33 30 10

+49 (0) 4 21 / 48 70 45 -

info@rosenboom-wzm.de

www.rosenboom-wzm.de

#1021-51910 · CNC Turning- and Milling Center

GILDEMEISTER - CTX 800 Beta V6 - - 2009 - Heidenhain ERGOline

Technical details

CNC lathe with driven tools, Y- axis and sub spindle - 3 jaw chuck SMW 315 BH main spindle - 3 jaw chuck SMW 250 BH sub spindle - chipconveyor - oil mist collector LTA - automatic door - coolant pistol - partly hollow spindle Ø 65 x 840 mm

- Gustav Schönberger GmbH

- Hünderstr. 14

- 74080 Heilbronn

- Deutschland

-

(0049)7131 46060

(0049)7131 460620 -

schoenberger@gsh-maschinen.de

www.gsh-maschinen.de

#1036-032986 · CNC Turning- and Milling Center

DMG-GILDEMEISTER - CTX Gamma 1250 TC - - 2009 - Sinumerik 840D SL

Technical details

Siemens 840D sl control 3-jaw chuck milling spindle (B-axis) Y-axis steady rest 120-fold chain magazine (Capto C6) tail stock chip conveyor coolant device Technische Daten / technical details: max. Umlaufdurchmesser / max. rotary diameter 700 mm max. Drehdurchmesser / max. turning diameter 700 mm max Drehlänge / max. turning length 1250 mm X-Achse / X-axis 800 mm Z-Achse / Z-axis 1300 mm Y-Achse / Y-axis +-210 mm Drehzahl Frässpindel /speed of milling head 12000 UpM / rpm Drehzahlbereich Spindel/ spindle speed 5000 UpM / rpm Schwenkbereich B-Achse/swivel range B-axis +-120 ° Eilgang B-Achse/ rapid feed B-axis 100 m/min Eilgang X,Z,Y / rapid feed X,Z,Y 50,50,50 m/min Antriebsleistung Spindel (40%ED) / drive capacity spindle (40%ED) 32 kW Gewicht der Maschine ca. / weight ca. 18500 kg Technische Daten, Zubehör und Beschreibung der Maschine sind unverbindlich - Technical data, accessories and description of the machine are not binding.

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9179 · CNC Turning- and Milling Center

GILDEMEISTER - CTX 410 V3 - - 2009 - CNC Pilot 4290 Heidenhain

Technical details

CNC Turning- and Milling Center Gildemeister - CTX 410 V3 - driven tool-stations - ca. 7.900h spindle-hrs.

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03779 · CNC Turning- and Milling Center

DMG MORI - CTX Beta 800 v 6s - - 2008 - Sinumerik 840D sl Siemens

Technical details

CNC - Turning- and Millingcenter DMG MORI - CTX beta 800 linear V 6 s - Sinumerik Operate und ShopTurn 3G - Spindle ISM 102 - Y-Axis+ c axis - WITH Steady with schip convoyer

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03751 · CNC Turning- and Milling Center

CMZ - TB 67 M - - 2008 - Fanuc 32 I MANUEL GUIDE

Technical details

CNC-Lathe with driven tools, short magazin barfeeder and partscatcher in very good condition. Equipment: - chipconveyor - 3-jaw-chuck - some toolholders JAPANES - 6 x driven toolholder - partscatcher - Touch setter WITHOUT BAR FEEDER

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-619 · CNC Turning- and Milling Center

MORI-SEIKI - NT 4250DCG/1500S - - 2008 - MSX-701 III

Technical details

Rapid traverse rate (X1, Z1 Axis) 50 m./min. Rapid traverse rate (X2 Z2 Axis) 30 m./min. Rapid traverse rate (Y Axis) 30 m./min. Rapid traverse rate spindle 2 ZS 30 m./mm. Rapid traverse rate B axis 40 rpm Rapid traverse rate C axis 250 rpm Spindle 1: Speed 4.000 rpm Number of speed ranges 2 Nose JIS A2-8 C axis in spindle 1 I Min indexing increment spindle 1 0.0001º Power 26/22 kW Max torque 724 Nm 3-jaw automatic chuck KITAKAWA B-212 A8 Chuck size 304 mm. Chuck hole 91 mm. Chuck speed 3300 rpm Spindle 2: Speed 4.000 rpm Through-spindle hole 91 mm. Nose JIS A2-8 C axis in sub- spindle 1 Min indexing increment spindle 2 0.0001º Power 26/22 kW Max torque 724 Nm 3-jaw automatic chuck KITAKAWA B-212 A8 Chuck size 304 mm. Chuck hole 91 mm. Chuck speed 3300 rpm Tool Spindle Direct drive spindle INCLUIDO/INCLUDED B axis indexing time 0.65s Min B-axis indexing increment 0.0001º Max B-axis indexing speed 100 min-1 Taper hole of rotary tool spindle Capto C6 Max Speed of the Head 12.000 rpm Milling Motol Power 18.5/11 kW Spindle torque 120/44 Nm Tool clamp 12.000 N Automatic tool changer: Tool system Capto C6 ATC positions 100 Max Tool diameter 70 mm. Mas tool diameter without 140 mm. Max tool length 400 mm. Max tool weight 8 k Tool-to -tool change 1.25 s

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9156 · CNC Turning- and Milling Center

SPINNER - TC 110 SMCY - - 2008 - 840D SolutionLine Siemens

Technical details

CNC Turning- and Milling Center SPINNER - TC 110 SMCY - Main- and Subspindle - C-Axis - Y-Axis - Tool-Drive - Software package "Turning with ShopTurn" - 840D SL option "remaining material detection and processing" "3D simulation of the finished part"

- AS Maschinenhandel

- Welserstr. 10e

- 51149 Köln

- Deutschland

-

+49 (0)22031864856

+49 (0)22031864857 -

mail@asmaschinenhandel.de

www.asmaschinenhandel.de

#2044-100108 · CNC Turning- and Milling Center

DOOSAN - Puma MX2500 LST - - 2008 - Fanuc 18 iT-B

Technical details

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20092 · CNC Turning- and Milling Center

DOOSAN - Puma MX 2500 LST - - 2008 - FANUC 18i TB

Technical details

- CNC control FANUC Series 18i TB - Milling Head (Capto C6) - lower Tool Revolver 12-fold, driven tools 5,5kW - ATC for 40 tools - main and sub spindle with C-Axis each - Chip Conveyor - Coolant with paperband filter ca 12.000h "Run Time"

Datasheet

Request / Contact

TOP Manufacturer:

GILDEMEISTER - MORI SEIKI - MAZAK - INDEX - KRAFT - DMG MORI - CMZ - DOOSAN - OKUMA - DOOSAN DAEWOO -