HANS - JÜRGEN GEIGER Maschinen-Vertrieb GmbH - Stockist for used machines

Machinelist:

Tool Room Milling Machine - Universal

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-727739 · Tool Room Milling Machine - Universal

MACMON - M 100 D - - 1988 -

Technical details

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-733375 · Tool Room Milling Machine - Universal

MACMON - ALG 100 C - - 1972 -

Technical details

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-684848 · Tool Room Milling Machine - Universal

DECKEL - FP 1 - - 1972 -

Technical details

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-593290 · Tool Room Milling Machine - Universal

DECKEL - FP 1 - - 1964 -

Technical details

Datasheet

Request / Contact

Universal Milling Machine

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-794086 · Universal Milling Machine

DECKEL-MAHO - DMU 35 M - - 2002 - Siemens Type 810 D

Technical details

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-337263 · Universal Milling Machine

DECKEL - FP 4 CC/T - - 1991 -

Technical details

Working range: Longitudinal stroke X axis 600 mm Vertical stroke Y axis 500 mm Cross stroke Z axis 500 mm Clamping size of angle table 530 x 900 mm Max. weight of workpiece on table 450 kg Distance from table to vertical spindle, min./max. 120 / 620 mm Distance from table to horizontal spindle, min./max. 156 / 656 mm Tool taper SK 40 Spindle speeds 0 - 6,300 rpm Feeds X, Y and Z Axes, max. 2 - 10,000 mm/min Quick feed X, Y and Z Axes 10,000 mm/min Spindle drive 8 kW Total electrical load, approx. 15 kW - 400 V - 50 Hz Weight, approx. 5,500 kg Accessories / Special Features * DIALOG 11 CNC Control in 4 axes with all the usual options, cycles, and subprograms. Graphic display and electronic hand wheel. * Vertical milling head can be pushed up manually so that the horizontal milling spindle is free. This is also served by the tool changer. * Tool magazine with positions for 26 tools, max. Ø 100 mm x length 300 mm. Max. weight 10 kg. * Completely covered working area with two sliding doors allows easy loading of table. * Coolant device. Condition : Good to very good. Machine can be inspected under power. Modern software! Delivery : Ex stock, as inspected. Payment : Net, after conclusion of contract. We always have a selection of CNC machining centres available. We have a Deckel FP 3 CC/T with 4th axis on stock at the moment.

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-736032 · Universal Milling Machine

HERMLE - UWF 600 CNC - - 1990 -

Technical details

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-589421 · Universal Milling Machine

BOHNER & KÖHLE - WF 3/12 TNC 426 - - 1979 -

Technical details

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-352402 · Universal Milling Machine

RECKERMANN - Kombi 900 Pony - - 1974 -

Technical details

Universal Production and Toolroom Milling Machine

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-534864 · Universal Milling Machine

BOHNER & KÖHLE - DP 6 A - - 1965 -

Technical details

Datasheet

Request / Contact

Bevel Gear Grinding Machine

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

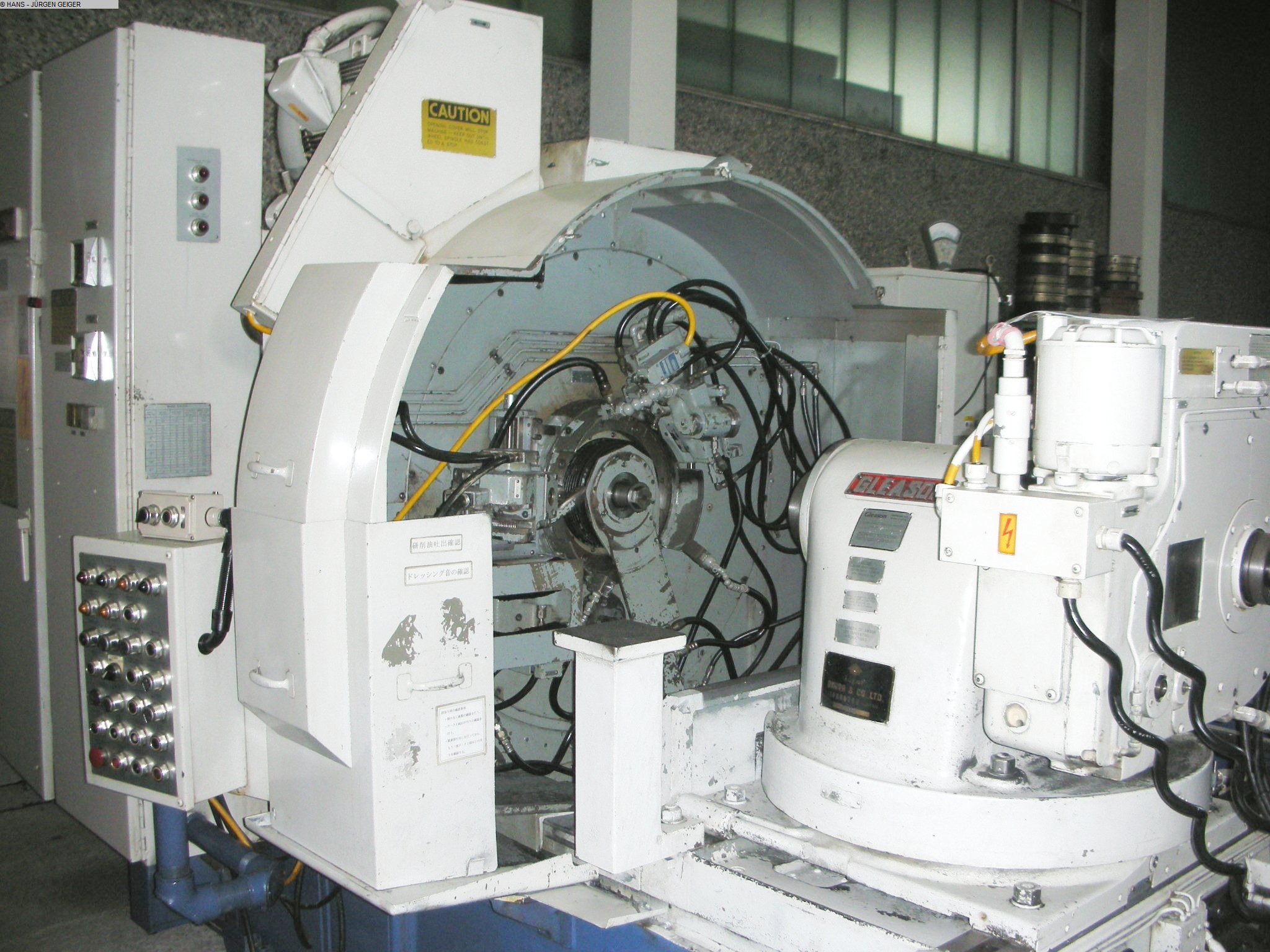

#1049-328540 · Bevel Gear Grinding Machine

GLEASON - PHOENIX 200 HG - - 1997 -

Technical details

Max. external Ø of workpiece 215 mm Tooth profile, height x width 16 x 40.65 mm No. of teeth 5 - 200 Max. tooth ratio 1 : 10 Grinding wheel Ø 51 - 190 mm Grinding wheel speeds 1,000 - 6,000 rpm X Axis (horizontal) 152 mm Y Axis (vertical) 178 mm Z Axis (slide base plate) 304 mm Distance from middle of machine to middle of workspindle 115 mm Axial speed 125 mm/sec Workpiece speeds 0 - 30 rpm Workspindle bore, conical 3 29/32 inch Total electrical load 20 kW - 380 V - 50 Hz Weight, approx. 10,000 kg Accessories / Special Features * FANUC CNC Control, Model 150 MB, for 7 axes, with monitor and direct input. Automatic calculation of all workpiece and grinding parameters. * Extensive coolant equipment with filter system, band filter, etc. * Driven grinding wheel dressing device with CNC dressing control for automatic compensation of form and diameter after every dressing. * Gear grinding is effected either in single component operation using a conical cup wheel (Gleason 30°), or with a cylindrical cup wheel. These grinding wheels can be made of CBN, or of traditional "dressable" aluminium oxide material (question of cost). Grinding with a conical grinding wheel is of advantage with regard to heat build-up and quality of tooth contact pattern. Therefore these pairs of bevel gears (for automotive industry) can be generated in high quality with consistent accuracy, economically, and with short set-up times. Condition : Very good - machine can be inspected here under power Delivery : Ex stock, as inspected Payment : Net, after conclusion of contract Thank you for your interest. We always have a good selection of gear machines available. Please let us know what you need.

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-304112 · Bevel Gear Grinding Machine

GLEASON - 120 / 888 W - - 1980 -

Technical details

Max. depth of tooth 10 mm Max. workpiece Ø (for clearance) 1,010 mm Max. external Ø of coupling 610 mm Sliding base withdraw 216 mm Max. distance from grinding wheel to workpiece nose 90 - 430 mm Max. weight of workpiece, including clamp 500 kg No. of teeth 32 to 150 Grinding wheel Ø, approx 152 - 320 mm Grinding wheel speeds, infinitely variable 0 - 3,600 rpm Work spindle bore 60 mm Total electrical load, approx. 15 kW - 380 V - 50 Hz Weight, approx. 9,500 kg Accessories / Special Features * Automatic roughing and finishing process via pre-settable counter and built-in feed cam. * Counter for number of teeth. * Counter for number of dressing cycles. * 2 built-on dressing units with three dressing diamonds for radius dressing, side dressing and wheel end dressing. * Built-on index plate for 48 teeth. * Separate coolant device with band filter. * Separate hydraulic unit. * Separate TRION oil mist exhaust. * Various small parts.

Datasheet

Request / Contact

Bevel Gear Lapping Machine

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-490759 · Bevel Gear Lapping Machine

KLINGELNBERG - LKR 400 A 100 - - 1974 -

Technical details

K L I N G E L N B E R G (Germany) Automatic Bevel Gear Lapping Machine Model LKR 400 A 100 Year 1974/1998 Serial No. 1890 Partially reconditioned and electrically modernized in 1998 by Welter Company _______________________________________________________ Max. Ø of crown gear 400 mm Adjustment of pinion spindle 160 / 250 mm Adjustment of crown gear spindle 115 / 265 mm Additional movements: Axial / distance / vertical, approx. + / - 2 mm Automatic tooth clearance 0 - 0.6 mm Module 1 - 10 Axial offset, up / down, each 50 mm (= axial offset travel from middle position) Bore hole of driving spindle 100 taper Bore hole of driven spindle 60 taper 6 spindle speeds 900 - 1,800 rpm Total electrical load 12 kW - 380 V - 50 Hz Weight 4,200 kg Accessories / Special Features * Hydraulic workpiece clamping for both spindles. * Automatic lapping process. Following function can be preset: Clockwise / anticlockwise movement, lapping torque, pulling and pushing movement, 4 lapping programs, etc. * Protective hood for crown gears with a diameter up to 400 mm, with automatic closing mechanism. * Separate switch cabinet. * Separate hydraulic unit, etc. Price, ex stock EUR 29,500.-- The lapping process employed by this machine greatly improves the running performance of bevel gear pairs. Pinions and gears are meshed by up to three additional movements (axial, radial and vertical) which are controlled by cams. Tooth flanks are smoothed with the help of lapping medium, and contact patterns are corrected as necessary.

Datasheet

Request / Contact

Bevel Gear Testing Machine

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-385316 · Bevel Gear Testing Machine

GLEASON - 513 - - 1975 -

Technical details

G L E A S O N (USA) Hypoid Spiral Bevel Gear Running Testing Machine Model 513 TESTER, Year 1975, Serial No. 721607 This machine is very suitable for precision production testing of spiral and hypoid bevel gears with shaft angle 90°. The gear spindle is vertical and the pinion spindle is horizontal. The pinion cone distance can be adjusted while the machine is working in order to find the optimal mounting position whereby the gear is "loaded" with a preset torque. The axial pinion position can be adjusted until the quietest meshing position of the traction flank is found. Likewise, the thrust flank can be tested during the return run. Marking compound is sprayed on both sides of the teeth so the flank contact pattern can be seen. Working cycles, as well as the positioning in the tooth gap, are automatic. The gear quality can be assessed by recording the harmonic frequencies, which are displayed on a separate monitor and which can be analyzed with a RHF Control. Machine can be used for soft testing of production parts, as well as for mating sets of hardened gears and pinions prior to lapping, and for final testing after lapping to select the optimum pinion mounting distance. Also ideal for lab work, processing, and quality control. Max. gear outside diameter, approx. 508 mm Max. pinion outside diameter, approx. 254 mm Axial cross angle 90 ° Offset of pinion spindle above/below gear spindle, max. 102 mm Diameter of taper hole, pinion spindle 99/95 mm Diameter of taper hole, gear spindle 56/55 mm Speeds of pinion spindle, infinitely variable 0 - 1,250 rpm Speeds of gear spindle, infinitely variable 0 - 1,250 rpm Spindle drive, approx. 5 / 7.5 kW Total electrical load, approx. 15 kW - 380 V - 50 Hz Accessories / Special Features * Large display for 1 / 2 / 3 harmonies, display for pinion distance, pinion speed, as well of gear torque in kg/torque, etc. * Hydraulic workpiece clamping. * Hydraulic slide clamping. * Tank for marking compound with mixer and pump, separate. * Separate switch cabinet. * Separate hydraulic unit. * Lots of spare parts, spare motors, etc. Condition : Good. Machine can soon be inspected under power. Delivery : Ex stock, as inspected. Payment : Net, after conclusion of contract.

Datasheet

Request / Contact

Chamfering and Deburring Machine

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-341998b · Chamfering and Deburring Machine

HURTH - ZK 200/1-TE CNC - - 1991 -

Technical details

CNC controlled milling machine for synchronous rings

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-347971 · Chamfering and Deburring Machine

PRÄWEMA - W 2 - 1 SYNCHROFORM - - 1991 -

Technical details

Workpiece Ø, min./max. 30 - 400 mm Number of teeth 6 - 150 Module range, max. 5 Tool holder shaft Ø SK 30 / 20 Tool speeds 4,000 rpm Spindle drive max. infinitely variable 1.8 kW Feeds, longitudinal and cross 0.001 - 12 m/min Workpiece speed, max. (1.5 kW) C Axis 2,000 rpm Workspindle slide 400 mm Tool speed, max. 3,000 rpm Tool holder SK 30 Total electrical load, approx. 16 kW - 380 V - 50 Hz Weight, approx. 10,000 kg Accessories / Special Features * BWO (HECKLER & KOCH) CNC Control model 785 H for altogether 7 axes. Input via monitor. The control has all the supervision and fault diagnosis features necessary for fully automatic working process. * 2 workspindle units, left and right, which can be set at any angle. * CNC controlled: Z and W Axes for tool cross slide. X and U Axes for tool longitudinal slide. * L and O Axes for milling spindle. C Axis for workspindle rotation. * Manually controlled: Tool slide rotary table (B and E Axes). Tool slide vertical infeed (V and Y Axes). Tilt of tool head (A and D Axes). All axes have digital display in the control. * Hydraulically operated workpiece clamping device in conjunction with an automatic loading device using workpiece feed / conveyor belt and swivelling loading device, as well workpiece control by air. * Coolant equipment with chip conveyor. * Noise protection cabin. * Central lubrication. * Built-on hydraulic unit. * Pneumatically driven safety doors. * Deburring device, etc. The machine uses the hypocycloidal milling principal, with electronically synchronized tool and workpiece axes for working straight roof-formed teeth, symmetric as well as asymmetric forms. Advantages are high precision and productivity. Condition : Good to very good. Machine can soon be inspected under power. Delivery : Ex stock, as inspected Payment : Net, after conclusion of contract Thank you for your interest. We always have a good selection of gear machines available on stock.

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-555393 · Chamfering and Deburring Machine

HURTH - ZK 7 - - 1975 -

Technical details

Datasheet

Request / Contact

Cold Rolling Machine

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-346254 · Cold Rolling Machine

EX-CELL-O - XK 225 - - 1987 -

Technical details

Max.Ø tool slide stroke 760 mm Max.Ø rack length 610 mm Length of workpiece between centres, approx. 500 mm Max. tooth width / profile width 92 mm Max. workpiece Ø 38 mm Tailstock stroke on outboard support, hydraulic, approx. 500 mm Module range 0.3 - 1.3 Total electrical load, approx. 24 kW - 380 V - 50 Hz Weight, approx. 10,000 kg Accessories / Special Features * KBH Workpiece Feed Device, standing parallel to the machine, at present set-up for feed-in and feed-out of shaft-formed workpieces, approx. Ø 16 x 200 mm long, with prism conveyor belt and lifting station for 2 shafts (blank and finished part), as well as workpiece positioning control. * Originally, external gears were formed on the machine using pinion cages (no. of teeth = 25), Ø approx. 32 mm x 14 mm long, workpiece Ø approx. 80 x 80 mm long. * Various accessories: * Separate switch cabinet. * Separate hydraulic unit, 900 l. * Coolant device in the machine. * Control panel with malfunction message in plaintext, etc. Roto Flo machines are ideal for mass production of smaller gears/profiles. The coldforming process is a lot faster and more economical than other chip removing methods. Workpieces are clamped between 2 live centres and 2 synchronous opposed directional coldforming racks simultaneously engage the workpart and start rotation. During rotation, the profile is formed successively within one stroke. In the calibrating zone, the profiling and surfacing performance of the tool are optimised. Profiles do not require a run-out. The coldforming process requires a rigid and heavy duty construction of the machine, which ensures the required precision over the years. Between 25,000 and 100,000 working cycles can be performed with one set of racks, also for serrations. Condition : Very good. Machine can be inspected under power. Delivery : Ex stock, as inspected. Payment : Net, after conclusion of contract. Thank you for your interest. We always have a good selection of gear machines available. Please let us know what you need.

Datasheet

Request / Contact

Gear Grinding Machine

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-575487 · Gear Grinding Machine

LIEBHERR - LCS 282 - - 1999 - LIEBHERR CNC

Technical details

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-507702 · Gear Grinding Machine

REISHAUER - RZ 301 AS - - 1993 -

Technical details

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-053024 · Gear Grinding Machine

REISHAUER - RZP 200 - - 1986 -

Technical details

5 machines in stock, YOM: between 1986 and 1990 Gear Æ, min./max. 55 / 120 mm Gear Æ for shaft-formed parts 80 mm Module (pitch 25.4 - 8.5) 1 - 3 No. of teeth, min./max. 13 / 80 Pressure angle 14 - 30 ° Helix angle, max. 40 ° Workpiece clamping length 145 - 420 mm Grinding worm Æ 300 - 400 mm Grinding worm width 25 - 40 mm Grinding worm speeds, infinitely variable (35 m/s) 1,650 rpm Feed range 0.4 - 4 mm/rev Total electrical load 20 kW - 380 V - 50 Hz Weight 7,500 kg Accessories / Special Features * REISHAUER Electronic Control = Easy programming of workpiece parameters and grinding process. * Automatic workpiece handling system for shaft-formed parts, approx. 350 mm long, including hydraulic loading and unloading device. Fully automatic production is possible. * Profile correction is possible for height and width crowning. * Separate hydraulic unit. * Separate switch cabinet. * Fully automatic profiling with a swivable diamond gear mounted on a shaft corresponding to the workpiece. Dressing intervals can be preset, with compensation. Price, ex stock, each DM 245,000.-- These machines are very suitable for grinding tooth flanks on large series of helical gears, with or without profile modification at a minimum cost. Separate electronically controlled drive of grinding worm and workpiece results in high precision and good surface quality of gears. Constant speed is controlled by an angular decoder. Grinding infeed is possible for the full profile depth as well as by a preset additional forwards and backwards movement of workpiece. Both flanks are continuously meshed and ground. Profile corrections during dressing process are made by the same method (by a diamond gear corresponding to the workpiece). All functions are controlled by a microprocessor. Code numbers for various errors are displayed.

Datasheet

Request / Contact

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-328981 · Gear Grinding Machine

HOEFLER - H 2500 / 1200 - - 1980 -

Technical details

Gear , min. / max. 180 / 2,500 mm Module 3 - 32 Helix angle, max. 10 - 35 ° Gear width for straight gears 1,200 mm Stroke length, approx. 100 - 1,200 mm No. of strokes 80 - 350 /min Stroke position adjustable 300 mm Stroke speed 4 - 40 mm Max. weight of workpiece, approx. 18,000 kg Min. / max. no. of teeth 16 / 576 Table size x bore 1,400 x 500 mm Grinding wheel Ø, approx. 500 mm Grinding wheel peripheral speed 34 m/s Total electrical load, approx. 45 kW - 380 V - 50 Hz Weight of machine, approx. 60,000 kg Accessories / Special Features: * Hydrostatic guides in grinding slide, table and in all other guideways. * Completely covered working area with sliding doors. * Automatic grinding process for various cycles, with settings for roughing, finishing, fine finishing and automatic dressing cycle after preset number of teeth. * Profile correction is possible via appropriate dressing, as well as additional movement of grinding slide (depth and width crowning). * Approx. 50 change gears. * Grinding slideTilt display device. * Large coolant device with band filter and oil mist exhaust. * Separate switch cabinet. * Separate hydraulic unit. * Separate oil cooling unit. Condition : Very good. Machine can soon be inspected in our showrooms. It is not under power at present. Delivery : Ex stock, as inspected. Payment : Net, after conclusion of contract. The machine comes directly from a first class gear factory, where it was grinding Quality 5 - 6. Grinding diagrams are available. This type and quality of machine is rarely available. Thank you for your interest. We always have a good selection of gear machines available. Please let us know what you need.

Datasheet

Request / Contact

Gear Hobbing and Shaping Mach. -combined

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-425442 · Gear Hobbing and Shaping Mach. -combined

PFAUTER - PA 300 SHOBBER - - 1979 -

Technical details

Gear hobber with gear shaping device, 2-cut cycle

Datasheet

Request / Contact

Gear Hobbing Machine - Horizontal

- HANS - JÜRGEN GEIGER

- James-Watt-Str. 12

- 72555 Metzingen

- Deutschland

-

(0049)-7123-18040

(0049)-7123-18384 -

geiger@geiger-germany.com

www.geiger-germany.com

#1049-473370a · Gear Hobbing Machine - Horizontal

MIKRON - A 35/36 CNC - - 1992 -

Technical details

Datasheet

Request / Contact

Hans - Jürgen Geiger Maschinen-Vertrieb GmbH

James-Watt-Str. 12

Contact Trader

Hans - Jürgen Geiger Maschinen-Vertrieb GmbH

James-Watt-Str. 12

72555 - Metzingen

Deutschland

(0049)-7123-18040

(0049)-7123-18384

geiger@geiger-germany.com

www.geiger-germany.com

Contact person:

James-Watt-Str. 12

72555 - Metzingen

Deutschland

(0049)-7123-18040

(0049)-7123-18384

geiger@geiger-germany.com

www.geiger-germany.com

Contact person:

Machine category

Abfallschere · Abkantpresse - hydraulisch · Abwälzfräs- und Stoßmaschine -kombiniert · Auswuchtmaschine · Bandsäge - horizontal · Bandsäge - Vertikal · Bandsägeautomat - Horizontal · Bearbeitungszentrum - Horizontal · Bearbeitungszentrum - Universal · Bearbeitungszentrum - Vertikal · Blechentgratungsmaschine · Bohr- und Fräsmaschine · Bohrerschleifmaschine · Bohrmaschine · Bohrwerkstisch · Bügelsägeautomat · CNC Drehmaschine · CNC-Karusselldrehmaschine - Einständer · Doppelscheibenschleifmaschine · Doppelscheibenschleifmaschine - vertik. · Doppelseitige Schleifmaschine · Drahterodiermaschine · Dreh-,Schwenk-, und Kipptisch · Drehmaschine - zyklengesteuert · Einständer - Ziehpresse - Hydraulisch · Einständerpresse - Hydraulisch · Entgratmaschine · Federprüfmaschine · Feinschleifmaschine · Flachschleifmaschine · Flachschleifmaschine - Horizontal · Formfräser-Schärfmaschine · Fräsmaschine - Universal · Fräswerkzeuge · Futterautomat - Einspindel · Gewinde-Schnecken-Schleifmaschine · Gewindefräsmaschine · Gewinderollmaschine · Gewindeschleifmaschine · Gewindewirbelmaschine · Graviermaschine · Hobel-, Fräs- und Schleifmaschine · Hochfrequenzspindel · Hochgeschwindigkeits Bearbeitungszentrum · Honmaschine - handbetätigt · Honmaschine - Innen - Vertikal · Hydraulische - Doppelständerziehpresse · Hydraulische - Viersäulenpresse · Hydraulische - Zweisäulenpresse · Härteanlage - Induktion · Härteofen · Innenschleifmaschine · Kaltkreissäge · Kaltkreissäge - Vertikal · Kaltwalzmaschine · Kegelrad - Läppmaschine · Kegelrad-Prüfmaschine · Kegelradschleifmaschine · Keilwellenschleifmaschine · Koordinatenmeßmaschine · Koordinatenschleifmaschine · Kreissägenautomat · Kurbelwellenbandfinishmaschine · Langdrehautomat · Lehrenbohrwerk - Vertikal · Leit- und Zugspindeldrehmaschine · Leiterplattenfertigungsmaschine · Läppmaschine · Messmaschine · Nutenziehmaschine · Oberfräsmaschine · Ofen - Elektro · Plandrehbank · Plattenbohrwerk - Horizontal · Plattensägen vertikal · Profilprojektor · Präzisionsbandsäge · Punktschweißmaschine · Radialbohrmaschine · Reihenbohrmaschine · Richtmaschine · Richtpresse - Doppelständer · Rißprüfmaschine · Rundschleifmaschine - Außen · Rundschleifmaschine - Universal · Rundtischflachschleifmaschine - Vertikal · Rundtischflächenschleifmaschine - Horiz. · Schabrad-Schärfmaschine · Schleifscheibenprofiliergerät · Schneidradschärfmaschine · Schweißanlage · Schwenkbarer - Rundtisch · Schwenkbiegemaschine · Senkerodiermaschine · Sonderfeinbohrmaschine · Sondermaschine · Spitzenlose - Rundschleifmaschine · Stanzautomat - Doppelständer · Strangpressen · Säulenbohrmaschine · Tafelschere - hydraulisch · Tafelschere - mechanisch · Teilapparat · Tieflochbohrmaschine · Tischbohrwerk · Trennschleifmaschine · Tuschierpresse · Universal - Rundtisch · Vorschubapparat · Werkzeugfräsmaschine - Universal · Werkzeugschleifmaschine · Werkzeugschleifmaschine - Universal · Wickelmaschine · Wärmeofen · Zahnflankenschleifmaschine · Zahnkantenfräsmaschine · Zahnrad-Abwälzfräsmaschine - horizontal · Zahnrad-Abwälzfräsmaschine - vertikal · Zahnradhonmaschine · Zahnradprüfmaschine · Zahnradschleifmaschine · Zahnradstossmaschine · Zahnstangenfräsmaschine · Zentrumschleifmaschine · Zugprüfmaschine ·