Sheet metal working - shaeres - bending

Machinelist: Sheet metal working / shaeres / bending

Stamping and Punching Machine

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON055 · Stamping and Punching Machine

NN - - - -

Technical details

Pipe cutting machine Templates: 19/25 mm Manual operation

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON142 · Stamping and Punching Machine

Peddinghaus - 210 Super 20 - - -

Technical details

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON178 · Stamping and Punching Machine

HPG - C110 - - -

Technical details

Brand HPG Machine no PON178 Type C110 Hydraulic control Including various punches.

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON162 · Stamping and Punching Machine

LVD - Strippit Delta 1250 TJ - - - Fanuc

Technical details

CNC brand: Fanuc CNC model: Series 180i PB Year of make: 2006 Capacity: 20 T Capacity: 6,4 mm Round: 25 mm ø X/Y: 1250 x1250 mm with overtake till 2.500 mm Strokes per minute: 30 incl. Roller tables and various punches

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON152 · Stamping and Punching Machine

Raskin Suisse - - - -

Technical details

Punching bracket Various punch brackets in stock: 1 x 15 JL200 4 x 15 JL240 0 x 25 JL200 5 x 25 JL250 5 x 35 JL270 0 x 50 JL290 1 x 100 JL250

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON161 · Stamping and Punching Machine

NN - 75 - - -

Technical details

Capacity: 75 T Punch unit: 20 mm Round: 30 mm ø Strip: 10 x 480 / 20 x 330 mm Angle iron: 140 x 140 x 12 mm Throat depth: 350 mm Electric stop

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON158 · Stamping and Punching Machine

MUHR & BENDER - KLH 500/610 - - -

Technical details

Capacity: 50 T Round: 30 in 15 mm ø Throat depth: 650 mm

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON163 · Stamping and Punching Machine

KINGSLAND - 55XS - - -

Technical details

Brand Kingsland Type 55XS Capacity 55 T Round 45 mm ø Square 45 mm Strip angle iron Hydraulic control

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON164 · Stamping and Punching Machine

PEDDINGHAUS - Peddicat 500 - - -

Technical details

Brand Peddinghaus Type Peddicat 500 Capacity 50 T Strip angle iron Hydraulic control Machine size (lxwxh) 1.000 x 700 x 1.700 mm Machine weight 900 kg

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON168 · Stamping and Punching Machine

Nippon - - - -

Technical details

Brand Nippon Hand punch Various punches Hydraulic unit: Enerpac IP54

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON169 · Stamping and Punching Machine

MUBEA - KBL 11N - - -

Technical details

Brand Mubea Type KBL 11N Machine dimensions (L×W×H) 1.500 x 1.300 x 1.900 mm Punch unit 30 x 9 mm Round 33 mm ø Square 30 ø Strip 100 x 7 angle iron 60 x 8 Scissors 200 mm

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON171X · Stamping and Punching Machine

PEDDINGHAUS - Peddi - - -

Technical details

Brand Peddinghaus Type Peddi Machine dimensions (L×W×H) 1.000 x 600 x 1.400 mm Round 30 mm ø Square 25 ø Strip angle iron 50 corners 40 Scissors 150 mm

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON170 · Stamping and Punching Machine

PEDDINGHAUS - 210/11 S - - -

Technical details

Brand Peddinghaus Type 210/11 S Machine dimensions (L×W×H) 1.500 x 1.000 x 1.800 mm Capacity 40 T Round 34 mm ø Square 30 ø Strip 120 x 12 angle iron

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON174 · Stamping and Punching Machine

Flutec - HP 1-1 - - -

Technical details

Brand Flutec Type HP 1-1 Flutec HP 1-1.70/420-LRD 6330M420-C-C-G24 Hand punching machine

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-PON179 · Stamping and Punching Machine

Geka - Hydracrop 80 SD - - -

Technical details

Brand Geka Machine no PON179 Type Hydracrop 80 SD Year of make 2010 Machine dimensions (L×W×H) 2.200 x 1.200 x 2.000 mm Capacity 80 T Punch unit 40 ø x 14 mm Round 45 mm ø Square 45 ø angle iron 130 x 130 x 13 Scissors 150 mm Throat depth 500 mm

Straightening Machine - Cold Plate

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20058 · Straightening Machine - Cold Plate

SKET - UBR 40 x 3150/7/12 - - 1983 -

Technical details

fully complete equipped with roller tables.

Datasheet

Request / Contact

Straightening Plant

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-04306 · Straightening Plant

MUBEA - Profi - - 1970 -

Technical details

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ Please note: The machine is dismantled and ready for loading. It is not possible to show it under power or make a video. Our offer includes already the best pictures. So we don’t have and won’t send additional pictures. ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

Strapping tool

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

Datasheet

Request / Contact

Strip Straightening Machine

- Goedicke Werkzeugmaschinenhandels GmbH

- Heinz-Nixdorf-Str. 2

- 74172 Neckarsulm

- Deutschland

-

+49-(0) 7132–999 360

+49-(0) 7132–999 3690 -

info@goedicke.com

www.goedicke.com

#1048-740263 · Strip Straightening Machine

MÜLLER WEINGARTEN - - - - SIEMENS S7

Technical details

Technical description : SCOPE OF DELIVERY/ COMPONENTS: - Coil carrier with separate crop shear - single sided de-coiler, - max coil width 2000mm, max weight 30tons - Two exchangeable straightening units ( cassette type ) with 13 straightening rolls, max blank thickness 1.8mm, max. blank width 2000mm - Loop pit - Roll feeder with roll diameter 220 mm, feed length max 4000mm - Monitoring of oil film thickness via scanner - Mechanical Blanking Press MUELLER WEINGARTEN VK 800.28.35 ( 1983) * with max. 55 strokes per minute * Table dimensions (clamping surface 2800 x 2800 mm * 2 Changing tables and 350mm stroke travel - FIRST NSM Blank de-stacker unit with 2 unloading stations - Max. blank dimensions 4000 x 2000mm - Conveyance speed 30 - 150 meters per minute - Packet weight max. 12000 kgs - Packet height max. 650 mm. (On this part finishing for side panel cutouts via controlled dies) - SECOND NSM unloading and stacking unit (90° towards flow through) - for smaller blanks and form blanks. - max. size 1650 x 800 mm - max. heigth with pallet = 450 mm. PERFORMANCE: 240 to 270 tons cut blanks per day in a 3 shift operation Description of condition : Blanking system for OUTER SKIN PANELS, with straightening machine cassettes to change. This system is "COIL CUT" capable. Video at: https://www.youtube.com/watch?v=1_gz2WxMMO0&feature=youtu.be The complete conveyor system was revised in 2011: - SEW and Siemens components electronically synchronized: NEW - Cardan shafts of the straightening system: NEW - Hinge side guide: Optimized - Complete electrics and electronics (S7): NEW - Drive block of the press: • BEFORE: grease lubrication • NOW: Circulating oil lubrication Also: NSM destacking system with two stations each up to 4000 mm in length and a side NSM destacking system with max. blank dimensions of 1650 x 800 mm. = COIL CUT CAPABLE SYSTEM !! - 1 HUB = max. 4 PARTS through nesting and removal in longitudinal and transverse directions.

Datasheet

Request / Contact

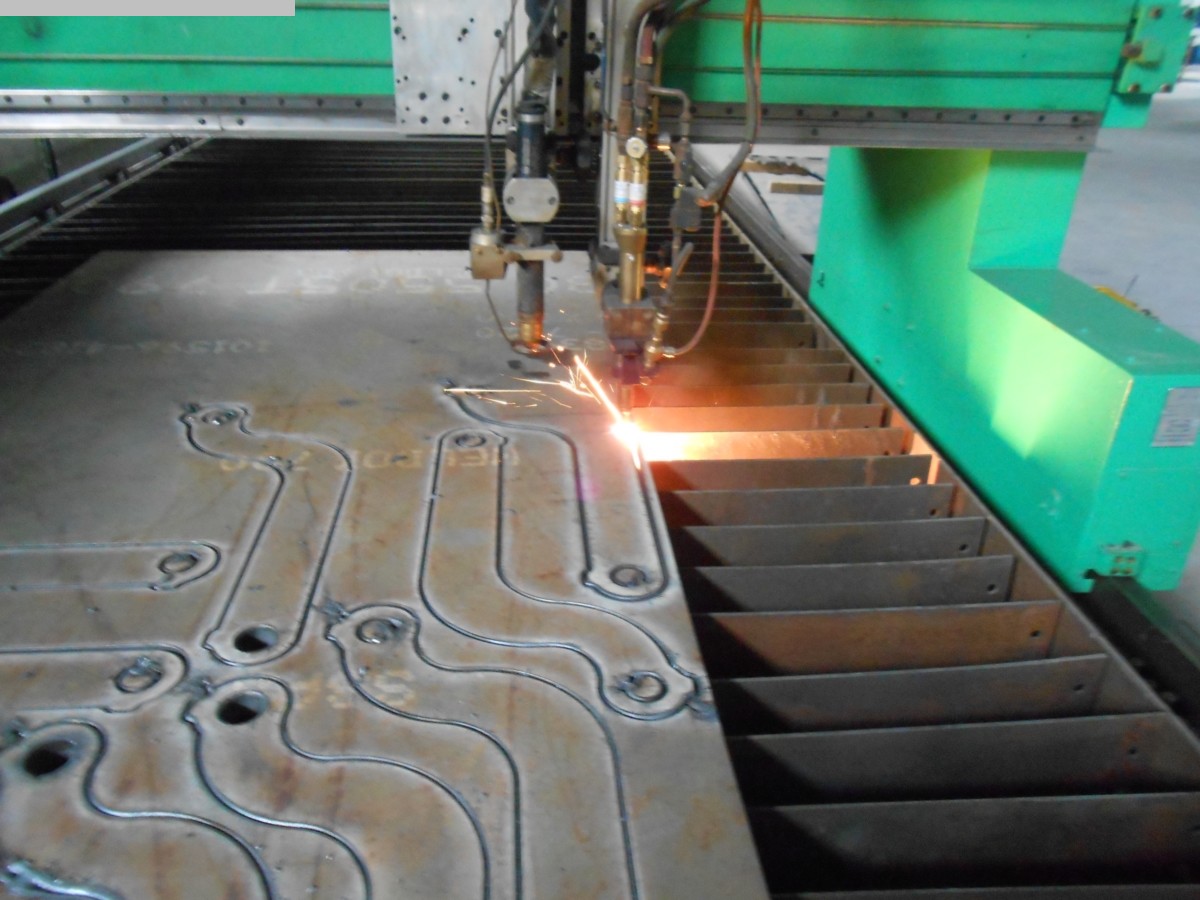

Thermal cutting machine

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2500025 · Thermal cutting machine

SATO - Compact Large - - NEU - CNC

Technical details

* Heavy machine bed with precision guides for quiet movement machine * A ball bearing cross carriage for height adjustment with 400mm vertical Hub * Thermal separation of the drive and cutting areas ensures the highest precision * Automatic height finding and torch height control during cutting * Torch holder with collision protection and automatic shutdown in the event of a collision * Installation or implementation of the machine using the plug & play method with a forklift, Ant or crane possible * 3-sided accessibility to cutting area through boom design SATOTEC suction table: The SATOTEC table system is characterized by a stable table construction max. cutting thickness of 150 mm. For cutting a workpiece thickness of 150 mm, oxyfuel cutting technology is required. The workpiece support frame has interchangeable ones placed at a 45° angle and 3 mm thick flat iron slats. The distance between the slats is 50 mm. Power source Kjellberg Q1500: * Precise plasma cutting of all electrically conductive materials from 0.5 to 60 mm both dry and under water * Recommended cutting range from 0.5 to 40 mm * Maximum piercing thickness 30 mm, increase possible with ProPierce Technology * Marking, notching and punching, including coated metallic materials * Inverter power source with digitally controlled, fully electronic process flow * Integrated cooling with partially automated filling and emptying Gas control: Fully automatically controlled, processor-controlled plasma all-gas console Q- Gas for cutting all metals Lantek Expert Cut Inside: CAD/CAM module integrated in the machine control Extraction TEKA EcoCube 5.5 kW Medium to be filtered: dry, fat-free or oil-free dust/smoke Filter area: 100 m² (4 cartridges of 25 m²) Filter cartridge: BIA M, Type Nano Degree of separation: 99% (according to BGIA test certificate) Filter control: automatic filter cleaning, PLC Fan performance: 4500 m³/h Motor power: 5.5 kW Connection voltage: 400V/50 Hz or 480V 60Hz. Current consumption: 11.5 A Current type: 3Ph+N+PE Fan structure: on the system, including silencer duct bend, right side Motor control: frequency converter Noise level: 75dB(A) + max 10 dB(A) with cleaning pulse Intake port: NW 250 mm via intake duct, left side Exhaust: via silencer duct bend Dimensions (W x D): approx. 800 x 800 mm System color: - Fan housing: Light gray - Cartridge housing: RAL 5007 brilliant blue Special equipment: - Locking hooks and toggle locks - Compressed air connection and condensate drain each mounted with one Bulkhead fitting - Compressed air connection with hose nozzle d=8mm - Provide the system with grounding bolts - Cable in UL version - EATON frequency converter on the left in the attached control cabinet

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E06175 · Thermal cutting machine

ZINSER - CNC 500 - - 1999 - CNC 500

Technical details

CNC flame cutting machine (propane gas and oxygen). With two propane burners (was converted from acetylene to propane) Track width 2750 mm Working width 2000 mm Working length 9000 mm Wall mounting for cables and gas pipes/trailing device incl. various spare parts (nozzles etc.) Working length 9000 x 2000 x 200 mm (sheet thicknesses cut here up to 120 mm) - Plasma cutting unit Kjellberg PA-S47 CNC (works with compressed air) - software MCC Cut, version 6.0116 with dongle and postprocessor - Complete documentation (drawings, various manuals, electrical diagram, operating instructions etc.) - TORIT extraction unit

Tryout Press - hydraulic

- Volz Werkzeugmaschinen

- Friedrich-Ebert Straße 78-80

- 58454 Witten-Annen

- Deutschland

-

+49 (0) 23 02 / 98 72 – 0

+49 (0) 23 02 / 98 72 - 50 -

anfrage@volz-witten.de

www.volz-witten.de

#1134-080000- · Tryout Press - hydraulic

VOLZ - MHP 60/750 - - 2022 -

Technical details

Datasheet

Request / Contact

- WeMa Antonius Pigge GmbH

- Barnstorfer Str. 3

- 49424 Goldenstedt

- Deutschland

-

+49 (0)444496700

+49 (0)4444967010 -

info@wema-pigge.de

www.wema-pigge.de

#2031-3530 · Tryout Press - hydraulic

RHTC - 100 TON M/H - M/C-2 - - 2022 -

Technical details

Movable cylinder (left-right) Integrated pressure manometer Pressure regulation Hydraulic unit with two speeds In height adjustable working table Joystick for the control of the piston Hand pump for precise press work

Datasheet

Request / Contact

- SKM Industriemaschinen

- Röntgenstr. 3

- 89264 Weißenhorn

- Deutschland

-

+49 (0) 7309 954 986 0

+49 (0) 7309 954 986 1 -

info@skm-maschinen.de

www.skm-maschinen.de

#2032-1142 · Tryout Press - hydraulic

HIDROLIKSAN - HD 200 - - 2021 -

Technical details

Producer: HIDROLIKSAN YOM: new Type: HD 160 Thrust: 160 ton. Stroke: 400 mm Throat depth: 480 mm Total power requirement: 5,5 kW Distance between frames: 1.200 mm Cylinder-Ø: 120 mm Dimensions (LxWxH): 1.800 x 1.000 x 2.550 mm Weight: 1.400 kg Additional information: • solid, welded construction • pressure cylinder lateral adjustable • operating electrical per switch lever / • pressure indication per Manometer • material support per cylinder, adjustable in height • CE-mark