Engelfried Maschinentechnik GmbH - Stockist for used machines

Machinelist:

Tenoning machine

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-2700 · Tenoning machine

HABERKORN - FZS Studio - - gebraucht -

Technical details

Haberkorn FZS 1 Studio tenoning and slotting machine Machine is still being checked ------------------------------------------------------ The compact tenoning and slotting machine for the unusual window constructions. If you have the highest demands on a tenoning and slotting machine and easiest handling, you can meet them with the FZS 1 Studio right choice. This single shaft tenoning machine with 3 automatic tool positions contributes to reducing downtimes through quick tool changes and a special swivel table for the production of studio windows and segments for Arched window. The studio table developed for this purpose has special features that... enable rational work. Precise angle degree display via rotary encoder with 1/10 degree display. display in the control panel. The splinter wood stays in place at every angle setting Tool cutting plane. The support and thus the tension of the workpieces is always immediate the slotting tools. Automatic length compensation through special guideway and compensation attack. Length stop 2300 mm Quick lock at 90 degrees position. crosscut saw ------------------------------------------------------ Spindle arrangement: top Three-phase motor: 3 KW Spindle diameter: 30mm Speed: 2,800 rpm Saw blade diameter: max. 400 mm - automatic brake with speed monitoring - Positioning horizontally via pneumatic cylinders with turret heads - Protective and extraction hood with extraction nozzle 100 mm D Slotting spindle ------------------------------------------------------ Power: 7.5 KW Speed: 4,000 rpm Spindle diameter: 50mm Usable length: 300 mm Tool diameter max.: 400 mm Cycle 100 mm for 3 tool positions Protective and extraction hood with extraction nozzle 180 mm D Automatic brake with speed monitoring Special equipment: - Automatic trolley drive fully electronically controlled with automatic spindle lifting Trolley with stepless feed control depending on the area the crosscut saw and the slotting tools. - Lasers for precise display of the saw cut on the workpiece. On/off switch on the control panel. -LAS extension 1m extension of the dimension rail for subsequent installation. -LAS slider Length stop with 3 stop flaps for external frame dimensions and the associated external wing dimensions Weight: 850kg (technical data according to the manufacturer - no guarantee!)

5.500 €

Datasheet

Request / Contact

Transport system

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

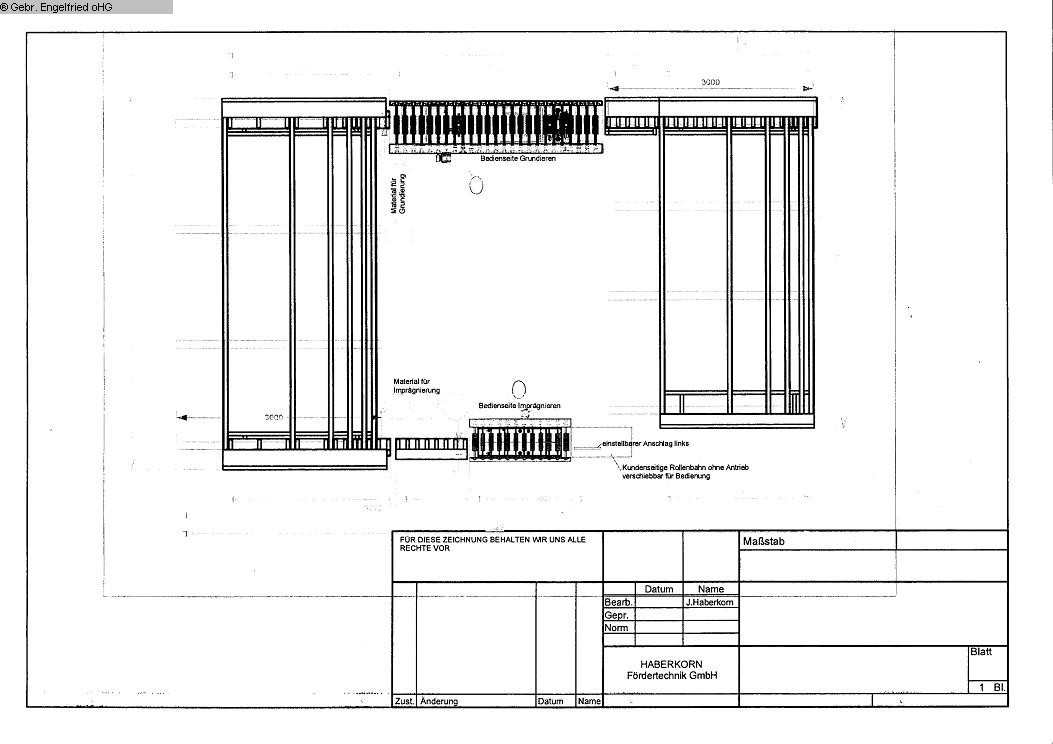

#1305-5943 · Transport system

HABERKORN - Beladefoerderer - Video - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5779 · Transport system

HABERKORN - Rueckfoerderer mit GLS Abwurf - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5745 · Transport system

HABERKORN - Foerderanlage nach Fluttunnel - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6049 · Transport system

HABERKORN - Ruecklauf fuer Umfaelzmaschine - - neu -

Technical details

Haberkorn return means for Umfälzautomat ************************************************** ********* For frame from 300 mm to 3000 mm for automatic Return consisting of: First cross roller conveyor approx 3100 mm long ------------------------------------------------- built-in conveyor belts for depositing the wing on the cross roller conveyor with about 10 mm stroke Driving speed of about 5-30 m / min. Roller diameter 80 mm Rollers with PVC coating Gear motor with 0.37 KW 2 Synchronized lifting device for cross roller conveyor -------------------------------------------------- ------------------------ built-in rollers with stepless drive about 5-30 m / min. max. 100 mm stroke Roller diameter 80 mm Rollers with PVC coating Synchronous storage of GG 25 hardened gears and rods 2 pneumatic cylinder 80 x 100 mm adjustable stops (top - down ) Synchronization via shafts and bevel gears 3 longitudinal conveyor for transport back ---------------------------------------------- Conveyor belts with polyester coated tread 50 mm wide, made in plastic guides Drive with spur gear motor 0.37 KW , about 5-30 m / min. Wing with more than 3000 mm can use the Be bypassed operator. control -------------- Siemens S 7, 24 VDC optical limit switches E-stop loop Fully installed with 16 A Euro plug 400 V AC, 2.5 KW, 50 Hz Color: --------- RAL 7035 light gray Construction , commissioning and instruction EUR 980,00 (technical details according to manufacturer - without guarantee ! )

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-662 · Transport system

HABERKORN - RFA - - neu -

Technical details

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-5375 · Transport system

HABERKORN - Ruecktransport_back transport - - neu -

Technical details

Neue Haberkorn Rückfördereinrichtung nach Vierseitenhobelmaschine ------------------------------------------------------- Förderanlage für Holzlängen von 300 mm-4200 mm Pos.1 Längs-Quer-Länsförderer ca.2451 x 1670 mm - höheneinstellbare Stützböcke (ca.800 mm - 1000 mm) - stufenlos angetriebene Rollenbahn ca.5-25m/min, - Rollendurchm.50mm, 140mm Rollenmantellänge - Übergabe auf Querförderer durch Heben-Senken der Rollenbahn - Querförderer mit 6 Stck. Traversen - Förderbänder 50mm breit, in Kunststoffbahnen geführt - Antrieb ca.5-25m/min, 0,37 KW - ca.1250mm von Anschlag zu Anschlag - Übergabe als Hebesenkeinrichtung - angetriebene PVC beschichtete Stahlrollen, Durchm.50mm, 140mm Mantellänge - Antrieb ca.5-25m/min, 0,37 KW - Rollenabdeckung nach HBG Pos.2 Förderband ca.3000 x 260mm - höheneinstellbare Stützböcke (ca.800 mm - 1000 mm) - angetriebenes Band ca. 5-25 m/min - Bandbreite 260 mm - Antrieb über Getriebemotor - Förderband auf Lenkrollen mit Bremse - Rollenabdeckung nach HBG Steuerung: Siemens LOGO 24 RCo, 24 V DC, optische Endschalter, Not-Aus-Schleife Fertig installiert mit 16A Eurostecker Anschluß: 400 V AC, 2,0 KW, 50 Hz Pneumatik: 6-8 bar, Verbrauch ca.12NL/min Farbe : RAL 7035 hellgrau CE nach EN 292 Teil1, EN 292 Teil 2, EN 294, EN 349, EN 418, EN 602-1EG Maschinenrichtlinie 89/392/EWG , EG Niederspannungsrichtlinie 73/23 /EWG Genannte Preise ab Werk zzgl. Verpackungs- und Transportkosten (Techn. Angaben laut Hersteller ohne Gewähr!)

Datasheet

Request / Contact

- Engelfried Maschinentechnik GmbH

- Elisabethenstr. 41

- 73432 Aalen

- Deutschland

-

(0049)07361-98660

(0049)07361-986640 -

info@engelfried.com

www.engelfried.com

#1305-6770 · Transport system

HABERKORN - Ruecktransport - - Neu -

Technical details

Haberkorn return conveyor approx. 2,451 mm x 2,170 mm ---------------------------------------------- base frame - Steel tube frame 50 x 50 x 2 mm - Height-adjustable trestles (approx. 800mm - 1000mm) - Conveyor system for wood lengths from 300mm to 4200mm - Conveyor system for wood widths up to 240mm Roller conveyor - infeed - Continuously driven roller conveyor approx. 5 - 25m/min - Drive via gear motor 0.37kW, vertical shaft and PU round belt - Roll diameter 50mm, 240mm roll jacket length with PVC jacket - Transfer to cross conveyor by lifting - lowering the roller conveyor - Roller cover according to HBG cross conveyor - Cross conveyor with 6 traverses - Conveyor belts PVC coated (green) 50mm wide, guided in plastic tracks - Continuously driven cross conveyor approx. 5 - 20m/min - Drive via geared motor 0.37kW - Approximately 1750mm lock to lock Roller conveyor - outlet - Continuously driven roller conveyor approx. 5 - 25m/min - Drive via gear motor 0.37kW, vertical shaft and PU round belt - Roll diameter 50mm, 240mm roll jacket length with PVC jacket - Transfer to cross conveyor by lifting - lowering the roller conveyor - Roller cover according to HBG ---------------------------------------------- Conveyor belt approx. 320mm x 3500mm base frame - Steel tube frame 50 x 50 x 2 mm - Height-adjustable trestles (approx. 800mm - 1000mm) - Conveyor belt for wood lengths from 300mm to 4200mm - Conveyor belt for timber widths up to 240mm - Conveyor belt on castors with brake tape - Continuously driven approx. 5 - 25m/min - Drive via geared motor 0.37kW - Tape PVC coated 260mm wide - Stop on both sides approx. 15mm ---------------------------------------------- Steering: - Ready to plug in with its own controller and logic - Siemens PLC, 24VDC - Siemens frequency converter - Optical limit switches and emergency stop loop - Ready installed with 16A Euro plug - Connection: 400V AC, 2kW, 50Hz ---------------------------------------------- Pneumatic: 6-8 bar, consumption approx. 16NL/min Colour: RAL 7035 light grey Basic EC Directive 2006/42/EC in accordance with 2006/95/EG Electrical Equipment (Low Voltage Directive) and 2004/108/EC EMC Directive ---------------------------------------------- Price of the above version ex works: on request! plus packaging and transport costs ---------------------------------------------- (Technical information according to the manufacturer without guarantee!)

Datasheet

Request / Contact

Profilo del commerciante: Engelfried Maschinentechnik GmbH

Contatta Trader

Engelfried Maschinentechnik GmbH

Elisabethenstr. 41

73432 - Alen

Germania

(0049)07361-98660">(0049)07361-98660

(0049)07361-986640

info@engelfried.com

www.engelfried.com

Elisabethenstr. 41

73432 - Alen

Germania

(0049)07361-98660">(0049)07361-98660

(0049)07361-986640

info@engelfried.com

www.engelfried.com

Profilo di Trader

Società Gebrüder Engelfried oHG

Elisabethenstrasse 41

73432 Aalen-Unterkochen

Germania![]() Tel. + 49 (7361) 9866-0 Werner e Florian Engelfried

Tel. + 49 (7361) 9866-0 Werner e Florian Engelfried![]() Tel. + 49 (7361) 9866-0 Florian Engelfried

Tel. + 49 (7361) 9866-0 Florian Engelfried![]() kom. 0602392773 Marian Grzeszkiewicz

kom. 0602392773 Marian Grzeszkiewicz![]() Teel.: + 49 (7361) 9866-19 Кирилл Суппес

Teel.: + 49 (7361) 9866-19 Кирилл Суппес

Fax.: + 49 (7361) 8431

(At) engelfried.com

Esposizione e magazzino:

zona industriale

Kapellenweg 25

73447 Oberkochen

Germania

Tel. + 49 (7364) 919323

Engelfried Maschinentechnik GmbH

Elisabethenstr. 41

Contact Trader

Engelfried Maschinentechnik GmbH

Elisabethenstr. 41

73432 - Aalen

Deutschland

(0049)07361-98660

(0049)07361-986640

info@engelfried.com

www.engelfried.com

Contact person:

Elisabethenstr. 41

73432 - Aalen

Deutschland

(0049)07361-98660

(0049)07361-986640

info@engelfried.com

www.engelfried.com

Contact person:

Machine category

Abläng- und Gehrungssäge · Abrichthobelmaschine · Absauganlage · Band- und Profilschleifmaschine · Bandsäge · Beschlagcenter · Bohr- und Dübeleintreibautomat · Bohr- und Dübeleintreibmaschine · Breitbandschleifmaschine · Clipsetzer fuer Holz-Alufenster · CNC-Bearbeitungszentrum · CNC-Bearbeitungszentrum Fenster u. Türen · Dickenhobelmaschine · Doppelgehrungssäge · Dreh- und Kipptisch · Ecklager- und Olivenbohrmaschine · Entstauber · Fensteranlage · Fensterlackieranlage · Fensterwerkzeuge · Formatkreissäge · Fräsmaschine · Furnierklebegerät · Furnierpresse · Füge- und Feinschnittmaschine · Glasleistensäge · Kantenschleifmaschine · Kapp- und Gehrungssäge · Keilzinkenanlage · Klammergeräte · Kombinierte Abricht- und Dickenhobelmasc · Kommissionswagen · Kompressor · Kragarmregale · Kreuzsprossenfräse · Lamellierpresse · Leimauftragsmaschine · Leimgerät · Längskreissäge · Längsschnittkreissäge · Minizinkenpresse · Montagestation · Olivenbohrmaschine · Optimierungskappsäge · Plattensägen vertikal · Profilwagen · Rahmen- und Langlochbohrmaschine · Rahmenpresse · Rollenbahn · Rundbogenfräsgeräte · Schleifmaschine · Schwenkfräsmaschine · Transportanlage · Transportwagen · Umfälzautomat · Untertischkappsäge · Verglasungs- und Kontrollpresse · Verleimstern · Vierseitenhobelmaschine · Werkstückrückführung · Werkzeug-Reinigungsgeräte · Zapfenschneid- und Schlitzmaschine · Zerspanen ·