CNC Turning- and Milling Center

Machinelist: CNC Turning- and Milling Center

CNC Turning- and Milling Center

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100139 · CNC Turning- and Milling Center

KRAFT - KT 620/2000 - - 2023 - FAGOR 8055 m. C-Achse

Technical details

New CNC lathe KRAFT KT 285/2000 with Fagor 8055. Made in Europe, Picture similiar. For more information please see the attached documents

76.560 €

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100527 · CNC Turning- and Milling Center

MICROCUT - LD65 (m. C-/Y-Achse) - - 2023 - SIEMENS 828D mit 15'' Touchscr

Technical details

+++SPECIAL PRICE+++SPECIAL OFFER+++ main features: -high speed -high spindle torque -big spindle bore -automatic forced lubrication -hardened and ground guideways -brand-new design eterior -CE certificate of TÜV Rheinland, Germany & ISO 9001 CQC, China All machines' functionalities will be checked and controlled before loading. The machines can be modified according to CE upon request. warranty: none

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-35469 · CNC Turning- and Milling Center

KRAFT - TC-2500LM (C-Achse)+Stangenla - - 2023 - Fanuc 0i TF und MANUAL GUIDE I

Technical details

brand new CNC turning center with Contains: 1. Control system Fanuc Oi-TD (8,4" LCD monitor) 2. X/Z-axis stroke 200/600 mm 3. X/Z-axis rapid traverse 30/30 M/MIN 4. Spindle motor 11 / 15 Kw 5. Spindle speed 3500 rpm (Belt driven type) 6. Spindle bearing dia. Ø 120 mm 7. Bar capacity Ø dia 64 mm 8. CS axis function 0.001 degree spindle positioning 9. Hydraulic Hollow chuck 10" x 3 jaws 10. Hyd. unit for chuck with air cooler 11. Power turret system 12 stations with BMT65 radial type turret disc (Tongtai made) 12. Manual tailstock stroke 500 mm + quill stroke 100 mm 13. Electrical cabinet with heat exchanger 14. Standard splash guide 15. Coolant unit 16. Transformer (power source 380V) 17. Chip conveyor H=1100 MM with trolley (chain type) 18. Machine color Tongtai White/ Dark grey 19. Three color warning light 20. Safety foot switch 21. Fanuc warranty (western Europe) Standard accessories 1. Soft jaws x 1 set 2. Rotating center x 1 pc (MT#4) Options: 1. CE mark 2. Tool presetter (manual) 3. Part catcher 4. Workpiece conveyor 5. Bar feeder (BF-1200) 6. Hard jaws x 1 set 7. Soft jaws x 5 sets 8. Spindle insert for bar x 8 pcs ( Ø12, 16, 20, 26, 30, 38 mm) 9. Added collet chuck (With adapter) (Ortlieb KSFB 60/8 type) 10. Manual guide I function + 10.4" screen

.1124-100429-20210913140417690713.jpg)

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100429 · CNC Turning- and Milling Center

Kraft (Pinacho) - SH 400-105x2000 - - 2023 - Fanuc Oi-TF

Technical details

Used CNC flatbed lathe series Pinacho, type STH 400-105 x 3.000 with user-friendly CNC control FAGOR, system 8055 with integrated turning cycles (similar to Siemens Shopmill). This CNC lathe with milling unit offers the following benefits: - reliable and precise lathe from Spain for medium-heavy workpieces - The integrated C-axis allows parts to be milled and drilled in one clamping. You can thus save time and money. - Use of reliable components from renowned manufacturers such as KORTA, FAGOR, Duplomatic and many more. - the service and spare parts supply is still secured for the next 10 years. - High availability of spare parts due to own spare parts warehouse at the manufacturer's premises - quick set-up due to hydraulic feed and hydraulic tailstock quill - effective chip removal by chain chip conveyor - Protection of operators and the environment through sliding doors at the front and protective wall at the rear (open on the right-hand side) - you are extremely flexible in the machining of your parts due to further extensive special accessories such as steady rests etc. - further accessories can be installed retrospectively if required This young CNC lathe with milling device has the following high-quality equipment: - CNC control FAGOR, model 8055 (for further information see appendix), easy to learn and user-friendly. - Z/X axis servo motors - Electronic handwheel for the X- and Z-axis - Servo spindle motor - coolant system - Spindle sleeve and fixed tip MK 6 - partial enclosure - Automatic transmission from Baruffaldi - Automatic lubrication system - Manual tailstock - work lamp - Levelling screws and nuts - Operating instructions and programming instructions in German language - CE version incl. CE declaration of conformity - for connection 400V, 50Hz, 3 phases In addition, the CNC lathe with milling device is equipped with the following special accessories: - C-axis", continuous positioning - 1 pc. 12-speed disc turret, make Baruffaldi, model TBHMA200-12 for driven tools with VDI 40 receptacle - 2 pieces radial tool holder for driven tools VDI 40, Type designation PRR-S-40-ER32/50-T - 1 axial tool holder for driven tools, BMT65-A-ER32/50-T - 1 piece hydraulic chuck, diameter 400mm, hydraulic cylinder diameter 92mm and hydraulic tailstock quill. - Renishaw tool measurement on the machine - 1 piece chip conveyor - 1 fixed steady rest for diameter range 10 to 300mm - 1 fixed steady rest for diameter range 300 to 530mm - 1 set of soft jaws for chuck diameter 400mm - 1 set of hard jaws for chuck diameter 400mm By the way, you can expect even more from us than this reliable and tested used one: - Advice and solution finding at your location - Organization of the transport of your machine to your factory - Installation, assembly, commissioning and handover ready for operation - spare parts supply - Control training for Siemens, Heidenhain and Fanuc - Trained service personnel in your area and much more. - 24/7 telephone availability - Fiscal intelligent trade-in of your old machine - Cheap financing, even without down payment, or rent for a certain period! You still have questions or something is missing? Just give us a call: 06158-8286715

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20232 · CNC Turning- and Milling Center

DMG MORI - CLX 750 V4 - - 2021 - Sinumerik 840 D SL

Technical details

equipped with: - CNC control Siemens 840D MultiTouch - C-axis, y-axis - 12-position tool turret VDI 50(4000 rpm, 12,5 kW) - Chip conveyor with coolant system - Hydr. 3-jaw chuck SMW BH-D 400/A2-11 - Hydr. tailstock - Suction unit approx. 710h Machine On Hours and 175 Spindle Hours

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100414 · CNC Turning- and Milling Center

KRAFT - KT 570/2000 (mit C-Achse) - - 2021 - FANUC O i TF

Technical details

New CNC lathe KRAFT KT 285/2000 with Fagor 8055. Made in Europe, Picture similiar. For more information please see the attached documents

.1124-200616-20160713102318094831.jpg)

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-200616 · CNC Turning- and Milling Center

KRAFT (JAP) - STH 500/3000 (C- und Y-Achse) - - 2020 (neu/new) - FANUC TF MG

Technical details

New CNC lathe KRAFT ST 500/3000 with Fanuc Oi TD Made in Europe For more information please see the attached documents

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100283 · CNC Turning- and Milling Center

KRAFT - TCS-2000LM (m. C-Achse) - - 2020 - Fanuc 0i-TF + MANUAL GUIDE I +

Technical details

brand new CNC slant bed lathe with 1. Control system Fanuc Oi-TD (8,4" LCD monitor) 2. X/Z-axis stroke 170/600 mm 3. X/Z-axis rapid traverse 30/30 M/MIN 4. Spindle motor 11 / 15 Kw 5. Spindle speed 4500 rpm (Belt driven type) 6. Spindle bearing dia. Ø 100 mm 7. Bar capacity Ø dia 51 mm) 8. Hydraulic Hollow chuck 8" x 3 jaws 9. Hyd. unit for chuck with air cooler 10. Servo driven turret system 12 stations 11. Manual tailstock stroke 500 mm + quill stroke 100 mm 12. Electrical cabinet with heat exchanger 13. Standard splash guide 14. Coolant unit 15. Transformer (power source 380V) 16. Chip conveyor H=1100 MM with trolley (chain type) 17. Machine color Tongtai white/Dark grey 18. Safety foot switch 19. Tricolor lamp 20. Fanuc warranty (western Europe) Standard accessories 1. Facing tool holders x 2 pcs 2. O.D. tool gaskets x 8 pcs 3. I.D. tool holder (dia 32 mm) x 4 pcs 4. Boring sleeve x 6 pcs (dia 8, 10, 12, 16, 20, 25 mm) 5. Drilling sleeve x 3 pcs (mt#1, 2, 3) 6. Soft jaws x 1 set 7. Rotating center x 1 pc (MT#4) installed Options: 1. CE mark 2. Tool presetter (manual) 3. Parts catcher 4. Workpiece conveyor 5. Bar feeder interface 6. Hard jaws x 1 set 7. Soft jaws x 5 sets 8. Manual guide I function + 10.4" screen warranty: 12 months on parts Machine is made by the biggest maker of machine tools in Taiwan, also builiding for wellknown japanese makers.

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-29998 · CNC Turning- and Milling Center

KRAFT - HS-22M mit Lader - - 2020 - Fanuc 0i TD mit Manual guide,

Technical details

+++SPECIAL PRICE+++SPECIAL OFFER+++ main features: -high speed -high spindle torque -big spindle bore -automatic forced lubrication -hardened and ground guideways -brand-new design eterior -CE certificate of TÜV Rheinland, Germany & ISO 9001 CQC, China All machines' functionalities will be checked and controlled before loading. The machines can be modified according to CE upon request. warranty: none

.1124-100159-20201211124955574013.jpg)

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100159 · CNC Turning- and Milling Center

KRAFT (JAP) - STS 500/3000 (C-/Y-Achse) - - 2020 - Fanuc 0ITF

Technical details

New CNC lathe KRAFT ST 500/5000 with Fanuc Oi TD Made in Europe For more information please see the attached documents

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03927 · CNC Turning- and Milling Center

CMZ - TA 30 Y - - 2019 - fanuc 32 i

Technical details

VERY NICE MACHINE ONLY 1900 SPINDEL HOURS SPINDEL BORE DIA 66 MM TURNING LENG 66 MM C AXIS MOWING TOOLS Y AXIS +40/-40MM FANUC 32 I CHIP CONVOYER

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03820 · CNC Turning- and Milling Center

CMZ - TA 15 15 YS 640 - - 2019 - FANUC 32 ITB

Technical details

VERY NICE MACHINE WITH FANUC 32 IT CHIP CONVOYOR SUP SPINDEL BAR FEEDER C AXIS AND Y AXIS + LIVE TOOLS

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100356 · CNC Turning- and Milling Center

KRAFT - TD-2500YBC (C-/Y-Achse und Geg - - 2019 - SIEMENS 828D (10,4"DISPLAY mit

Technical details

brand new CNC turning center with Contains: 1. Control system Fanuc Oi-TD (8,4" LCD monitor) 2. X/Z-axis stroke 200/600 mm 3. X/Z-axis rapid traverse 30/30 M/MIN 4. Spindle motor 11 / 15 Kw 5. Spindle speed 3500 rpm (Belt driven type) 6. Spindle bearing dia. Ø 120 mm 7. Bar capacity Ø dia 64 mm 8. CS axis function 0.001 degree spindle positioning 9. Hydraulic Hollow chuck 10" x 3 jaws 10. Hyd. unit for chuck with air cooler 11. Power turret system 12 stations with BMT65 radial type turret disc (Tongtai made) 12. Manual tailstock stroke 500 mm + quill stroke 100 mm 13. Electrical cabinet with heat exchanger 14. Standard splash guide 15. Coolant unit 16. Transformer (power source 380V) 17. Chip conveyor H=1100 MM with trolley (chain type) 18. Machine color Tongtai White/ Dark grey 19. Three color warning light 20. Safety foot switch 21. Fanuc warranty (western Europe) Standard accessories 1. Soft jaws x 1 set 2. Rotating center x 1 pc (MT#4) Options: 1. CE mark 2. Tool presetter (manual) 3. Part catcher 4. Workpiece conveyor 5. Bar feeder (BF-1200) 6. Hard jaws x 1 set 7. Soft jaws x 5 sets 8. Spindle insert for bar x 8 pcs ( Ø12, 16, 20, 26, 30, 38 mm) 9. Added collet chuck (With adapter) (Ortlieb KSFB 60/8 type) 10. Manual guide I function + 10.4" screen

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9173 · CNC Turning- and Milling Center

DMG MORI - CTX alpha 500 - - 2018 - Sinumerik 840 D sl Celos

Technical details

CNC - Turning- and MillingCenter DMG GILDEMEISTER - CTX alpha 500 - Very good condition - only 4.400 spindle hours - incl. extensive tool package

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100334 · CNC Turning- and Milling Center

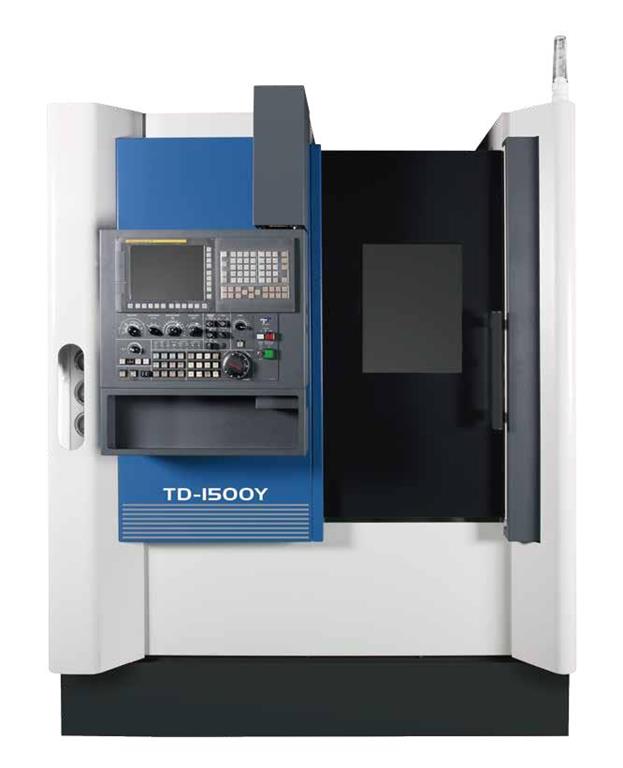

KRAFT - TD-1500Y (C-/Y-Achse) - - 2018 - Fanuc 0i TF + 10.4" LCD

Technical details

brand new CNC turning center with Contains: 1. Control system Fanuc Oi-TD (8,4" LCD monitor) 2. X/Z-axis stroke 200/600 mm 3. X/Z-axis rapid traverse 30/30 M/MIN 4. Spindle motor 11 / 15 Kw 5. Spindle speed 3500 rpm (Belt driven type) 6. Spindle bearing dia. Ø 120 mm 7. Bar capacity Ø dia 64 mm 8. CS axis function 0.001 degree spindle positioning 9. Hydraulic Hollow chuck 10" x 3 jaws 10. Hyd. unit for chuck with air cooler 11. Power turret system 12 stations with BMT65 radial type turret disc (Tongtai made) 12. Manual tailstock stroke 500 mm + quill stroke 100 mm 13. Electrical cabinet with heat exchanger 14. Standard splash guide 15. Coolant unit 16. Transformer (power source 380V) 17. Chip conveyor H=1100 MM with trolley (chain type) 18. Machine color Tongtai White/ Dark grey 19. Three color warning light 20. Safety foot switch 21. Fanuc warranty (western Europe) Standard accessories 1. Soft jaws x 1 set 2. Rotating center x 1 pc (MT#4) Options: 1. CE mark 2. Tool presetter (manual) 3. Part catcher 4. Workpiece conveyor 5. Bar feeder (BF-1200) 6. Hard jaws x 1 set 7. Soft jaws x 5 sets 8. Spindle insert for bar x 8 pcs ( Ø12, 16, 20, 26, 30, 38 mm) 9. Added collet chuck (With adapter) (Ortlieb KSFB 60/8 type) 10. Manual guide I function + 10.4" screen

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03991 · CNC Turning- and Milling Center

TAKISAWA - LA 250 YS - - 2017 - FANUC 31 ITB

Technical details

High Performance CNC Turning- and Milling Center with Y - Axis Chipconveyer, Counterspindle, driven tools, Y - Axis for eccentric Drilling and Milling works + - 60 mm C-Axis, screw brake, partcatcher, 3 driven tools as accessories, 10 static holder as accessories, , Toolsystem with one collet each for Main - and Subspindle, Tool Eye Measurement, Part catcher and part conveyer WHITOUT BAR LODER

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-033890 · CNC Turning- and Milling Center

DMG MORI - CTX beta 800 - - 2017 - Sinumerik 840D sl Siemens

Technical details

CNC - Turning- and Millingcenter DMG MORI - CTX beta 800 - Sinumerik Operate und ShopTurn 3G - Spindle ISM 76 - Y-Axis - WITH Tools + SUP SPINDEL

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

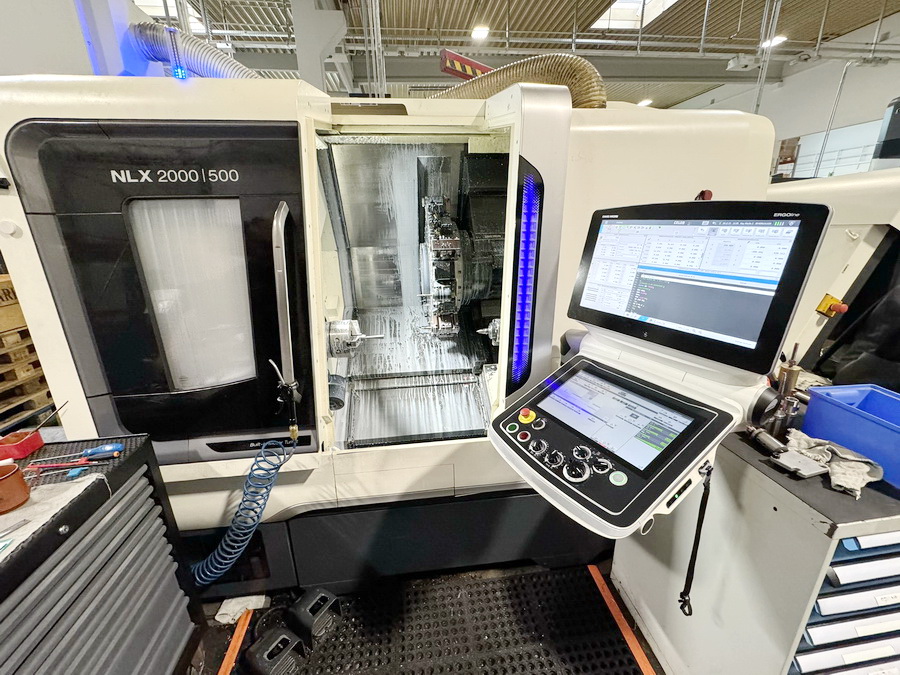

#1039-9155 · CNC Turning- and Milling Center

DMG MORI - NLX 2000 Y / 500 - - 2016 - ErgoLine CELOS

Technical details

CNC - Turning- and MillingCenter DMG MORI - NLX 2000 Y / 500 - C-Axis - Y-Axis - Tool-Drive - WITHOUT Toolholders!

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9119 · CNC Turning- and Milling Center

DMG MORI SEIKI - NT 6600 DCG / 3000 BS - - 2015 - Fanuc 31iB5 MAPPS

Technical details

CNC-HighPerformance-Turning- and Millingcenter DMG MORI SEIKI - NT 6600 DCG / 3000 BS - Main- and Subspindle - Tool-Spindle - 2x Three-Jaw-Chuck "SCHUNK - ROTA THW 500-128" - 1x Steady-Rest "SMW AutoBLOK - SLU 6ZS 125-460"mm - Operating-Hours: Power-On: ca. 23.000h Operating: ca. 6.400h Cutting: ca. 5.000h

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03812 · CNC Turning- and Milling Center

GILDEMEISTER - CTX beta 500 - - 2014 - 840 D SL SIEMENS

Technical details

CNC - Turning- and Millingcenter GILDEMEISTER - CTX beta 500 - Operating-Hours: Spindle-Runtime: ca.100h NEW SPINDEL -INTER FACE FOR Bar-Feede - C-Axis - Y-Axis CHIP CONVOYER CHUCK DIA 210 MM

- Detlef Jahn e. K.

- Gewerbepark 8

- 75331 Engelsbrand

- Deutschland

-

+49 (0)7235 974820

+49 (0)7235 9748224 -

info@langdreher.de

www.langdreher.de

#1092-02959 · CNC Turning- and Milling Center

INDEX - IT 600 - - 2014 - Fanuc 32i-B

Technical details

CNC universal lathe INDEX IT600, year of manufacture 2014 - The following accessories would be supplied: o 2-jaw chuck Schunk ROTA 2B 200 o approx. 40 sets of clamping jaws o Approx. 45 tool holders (1x driven), but without cutting tool holder/ cutting tool o Compact handling system FMB unirobot M-10iA-12-7P o 12x 7 pallets each for various blanks Option: It would be ideal if the buyer could machine forged blanks for us in the future. We cannot define an article list in advance, but the machine utilisation would be approx. 10% of the annual capacity. Previously used for machine loading with forged blanks in the moulds Angle, cross and T-piece. Can also be used for saw cuts. However, this does not require pallets, grippers and clamping devices are available.

- FIMOTEC

- 20 RUE AMPERE

- 67500 HAGUENAU

- Frankreich

-

+33 (0)388720247

+33 (0)388936066 -

FIMOTEC@WANADOO.FR

WWW.FIMOTEC.FR

#1105-03915 · CNC Turning- and Milling Center

DMG-GILDEMEISTER - CTX beta 1250 TC - - 2014 - SIEMENS 840

Technical details

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20063 · CNC Turning- and Milling Center

DMG MORI - CTX beta 1250 TC - - 2014 - Siemens 840D

Technical details

CNC - Turning and milling center - 5 axes - CNC control Siemens 840D Ergo Line with ShopTurn - C-axis (0,0001°) - Milling head with B-axis - Y-axis - Coolant device/paper belt filter - chip conveyor - Tool changer 24-fold (HSK A63) - Direct measuring system - IKZ 25bar - Tailstock

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2331 · CNC Turning- and Milling Center

HWACHEON - HI-TECH 200BL MC - - 2014 - FANUC 0i-TD

Technical details

Very good condition, low working hours ! Machine comes from a factory closure. * CNC control FANUC 0i-TD * C axis * 12-pos turret with powered positions (3,7/2,2 kW, 5000 rpm) * Internal cooling at 17 bar * Tailstock * Collet chuck up to 60 mm diameter * 3-jaw chuck, diameter 250 mm * 2 driven tool holders for machining the lateral surface * 2 driven tool holders for machining the end face

A CNC turning and milling center from LagerMaschinen will certainly be a great advantage to your small or medium-sized business. Choose from a CNC turning and milling center that fits your needs exactly. A CNC turning and milling center uses either one of multiple axes to calibrate and work wood metal or other hard materials. When purchasing a CNC turning and milling center from LagerMaschinen you'll be able to ensure quality control as well as to speak directly with sellers. Let LagerMaschinen's qualified experts assist you in your search for your next business machine.

CNC turning and milling center from LagerMaschinenA CNC turning and milling center (also known as a lathe) can be used for many different purposes. No matter what your end product a CNC turning and milling center from LagerMaschinen is just what you need. Used machines are more economically viable as well as kinder to the environment. A CNC turning and milling center from LagerMaschinen could be the logical solution for your production concerns. By purchasing your CNC turning and milling center through LagerMaschinen and its team of experts and professionals you'll not only find precisely what you're looking for but will also ensure that it lasts for a lifetime.

CNC turning and milling center - the most logical choiceNo matter what type of CNC turning and milling center you're looking for LagerMaschinen has what you need. Log on create and account and start shopping at LagerMaschinen today.

TOP Manufacturer:

GILDEMEISTER - MAZAK - MORI SEIKI - INDEX - DMG MORI - KRAFT - CMZ - DOOSAN - OKUMA - DOOSAN DAEWOO -