Laser Cutting Machine

Machinelist: Laser Cutting Machine

Laser Cutting Machine

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

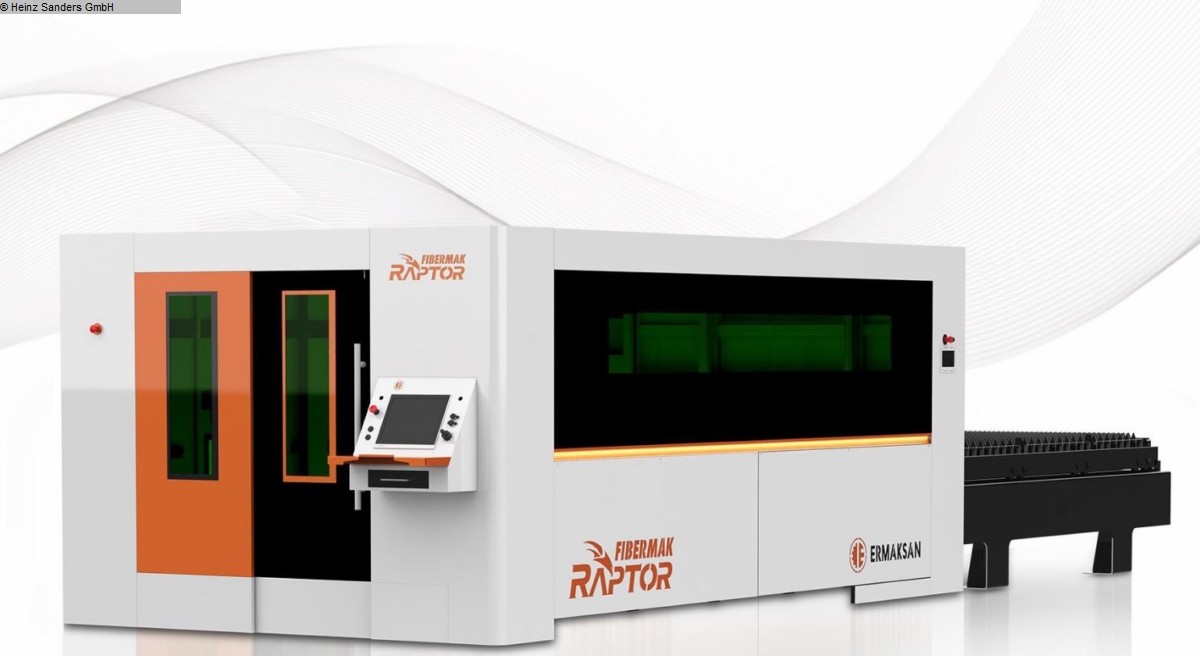

#1125-2500026 · Laser Cutting Machine

ERMAK - FIBERMAK RAPTOR 6KW - - NEU - CNC

Technical details

CUTTING CAPACITY: STRUCTURAL STEEL 25 mm STAINLESS STEEL 15 mm ALUMINUM 12mm BRASS 8mm COPPER 8mm MACHINE AXES: 4 axes [X, Y, Z, U ] CUTTING HEAD: Precitec ProCutter CAD/CAM SOFTWARE: LANTEK EXPERT CUT *4 servo motors for all axial movements *CNC CONTROL PANEL 15 5” touch screen *IPG laser sources and coolers integrated *Precitec Procutter cutting head system *AIR FILTER (compressed air filter) *CONVEYOR BELT under cutting area *Closed housing and specially coated filter protection windows *LOADING / DISCHARGING SYSTEM *PROPORTIONAL GAS AND PIPE SYSTEM

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7286 · Laser Cutting Machine

ERMAK - FIBERMAK SM 6000.3 x 1,5 - - NEU -

Technical details

Furnishing: - Resonator Ytterbium YLS 4000 compact - Beckhoff controller - Precitec ProCutter Automatic cutting head - autom. Lubrication system - CAD / CAM software LANTEK EXPERT CUT - 17 "touchscreen, keyboard, control panel - Collective conveyor under the cutting table - additional loading unit Cutting capacities: - normal steel 25 mm - stainless steel 15 mm - aluminum 12 mm - brass 8 mm - copper 8 mm Axes: - Machine axes: 4 axes (X, Y, Z, U) - max.axis speed: 100 m / min (simulated) - Axis speed X / Y: 100 m / min (single) - Positioning accuracy: + - 0.03 mm / min - Burning height: 125 - 200 mm Loading table: - Number of pieces 2 (35 seconds for changing) - automatic change of tables - max.load 2,500 kg. assisting gases: - mild steel - oxygen (0.5 - 25 bar) - stainless steel - nitrogen (0.5 - 25 bar) - Aluminum - compressed air or nitrogen (0.5 - 25 bar) including: - Compatible suction system - Sick light barrier safety device - Spare part basic supply package Why Fibermak? - Up to 3 times faster cutting compared to other laser technologies - Machines for cutting thin sheets - axes equipped with linear motors / Servo motors reach up to 141 m / min. - Accelerations up to 2G - Fiber laser is the green laser technology (Saving of at least 50% energy costs) - There is no need for laser gas mixing - There is no need for optical Components / therefore very low-maintenance - Save up to 50% per part through more efficient production - Extended options: cutting from reflective materials like aluminum, copper, brass etc., - In addition, precise cuts and smooth surface quality - Heavy-duty constructed frame, equipped with world-famous, durable, high-quality components - ERMAK passes the price advantage on to its customers thanks to its fast and high quality production - Creative design, constant, highest technology and quality - High reliability - High efficiency - High quality - CE declaration

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7255 · Laser Cutting Machine

ERMAK - FIBERMAK SM 4000.3 x 1,5 - - NEU -

Technical details

Furnishing: - MOMENTUM GEN - 2 fiber laser cutting machines 3,000 x 1,500 mm - Ytterbium YLS 4000 compact resonator (4 kW) - PRECITEC PROCUTTER laser cutting head - CAD / CAM software BECKHOFF - Controller CP 6242 - 17 "touchscreen, keyboard, control panel, alphanumeric keyboard - Collective conveyor under the cutting table - additional loading unit Cutting capacities: - normal steel ... 20 mm - stainless steel ... 12 mm - aluminum ... 10 mm - brass ... 6.0 mm - Copper ... 5.0 mm Workspace: - max .: 3,000 x 1,500 mm Axes: - Machine axes: 4 axes (X, Y, Z, U) - max.axis speed: 100 m / min (simulated) - Axis speed X / Y: 100 m / min (single) - Positioning accuracy: + - 0.03 mm / min - Burning height: 125 - 200 mm Loading table: - Number of pieces 2 (35 seconds for changing) - automatic change of tables assisting gases: - mild steel - oxygen (0.5 - 25 bar) - stainless steel - nitrogen (0.5 - 25 bar) - Aluminum - compressed air or nitrogen (0.5 - 25 bar) included : - Compatible suction system - Light barrier safety device - Spare part basic supply package Why Fibermak / Fiberlaser? - Up to 3 times faster cutting compared to other laser technologies - Machines for cutting thin sheets - Axis speed: reach up to 141 m / min. - Accelerations up to 2G - Fiber laser is the green laser technology - Saving of at least 50% energy costs) - There is no need for laser gas mixing - There is no need for optical components - therefore, among other things, very low-maintenance - Save up to 50% per part through more efficient production - Extended options: cutting reflective materials * like aluminum, copper, brass etc., - In addition, precise cuts and smooth surface quality - Heavy-duty constructed frame - equipped with world-famous, durable, high-quality components - Creative design, constant, highest technology and quality - High reliability - High efficiency - High quality - CE declaration

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-1386 · Laser Cutting Machine

HESSE by DURMA - HD-FO 2kW - - 2023 -

Technical details

Special promotion for stock machine Including commissioning and training (within Austria) Fiber laser HESSE HD-FO made by DURMA The HD-FO is our compact entry-level model. Control, laser source and cooling are integrated into the systemto keep the overall dimensions as small as possible. The manually extendable table is moved out of the side of the machine for loading and unloading. The cutting head has automatic focus adjustment. This makes the system a particularly economical, fast and very easy to operate production machine. The system consists of the following components: Manual loading and unloading table Encapsulated cutting room with protective glazing CNC graphic control with touchscreen Laser source IPG YLR Cutting head with automatic focus adjustment Integrated cooling unit for cutting head and laser source CAD/CAM software LANTEK for programming including autonesting Positioning laser Sheet check system (automatic detection of sheet position and dimensions) Automatic nozzle cleaning Slug box Working area lighting Multi-chamber suction system Remote maintenance access Equipped according to CE guidelines INCL. FOLLOWING SPECIAL EQUIPMENT: suction unit with filter Lantek Inside software licence with integrated camera (programming also directly at the machine) DIMENSIONS: Lenght of Guiding Machine: 5.600 mm Width of Guiding Machine: 2.700 mm Height of Guiding Machine: 2.130 mm Height of Guiding Machine when loading door are open: 2.725 mm Length of exhausting unit: 2.500 mm Width of exhausting unit: 1.400 mm Dimensions according to layout plan 8.500 x 5.500 mm OPTION: exhaust unit with filtersincl. Further options as Durma cloud on request.

169.900 €

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-92160 · Laser Cutting Machine

DURMA - FL-3015-L-6kW - - 2019 -

Technical details

demonstration machine FANUC 6000 W fiber laser source, automat. beam centering, DENER Smart Nest, Air Dryer, DENER Filter, Camera & Surveillance, air-conditioned control cabinet, Precitec Procutter cutting head, shuttle table, automatic nozzle cleaning, central lubrication, scrap pan for small parts etc. dirt, METALIX Pronest automatic nesting, multi-chamber suction system, warning lamp

- PTF GmbH

- Kreuzsteig 6

- 72479 Straßberg

- Deutschland

-

+49 7574 93 622 83

+49 7574 92 17 24 -

info@ptf-maschinen.de

www.ptf-maschinen.de

#2054-3211 · Laser Cutting Machine

Amada - Ensis AJ 6kW - - 2019 -

Technical details

- Broziat GmbH

- Vorwerker Str. 62a-64

- 23554 Lübeck

- Deutschland

-

+49 451 40 40 19

+49 451 40 73 93 -

info@Broziat.de

https://broziat.com

#2040-100512 · Laser Cutting Machine

TRUMPF - TruLaser 5030 Fiber (L68) - - 2018 -

Technical details

The machine is in good condition. 1. Option: Machine installation, operator training at buyers location and partially refurbishing including function guaranty: Surcharge 14.800 € plus Transport and traveling costs 2. Option: Workshop refurbished machine including technical approval by manufacturers’ directive at our workshop. Machine installation, operator training and free delivery of spare parts for 6 months after installation. Surcharge: 38.300 € plus Transport and traveling costs. Delivery time +6 weeks. Standardequipment machine: - closed machine frame with integrated laser unit, - movement unit for highly accurate processing, - Toryue-drive in combination with linear direct drive, - closed beam line, - a cutting head strategy, - cooling unit, - automatic pallet-changer in the longitudinal direction, - Conveyor, - 17" touch colour screen, - Work space lighting, - position laser diode, - spray device, - PierceLine, - NitroLine, - PlasmaLine Cutting head - LensLine, - Lens cutting head with 250mm focal length, - ControlLine Control - workshop programming, - simple workshop programming dir. Of DXF, - integrated technology files, - shutdown, - production plan, - programmable cutting gas pressure selection, - SprintLine, - ContourLine, - Microweld, - FastLine, - AdjustLine, - Teleservice, - diagnostic functions, - online-help, - FlyLine Date transmission - USB-interface, - RJ-45 network, Safety - CE-identification, - light barriers, - laser monitoring system, - more chambers extraction plant, - compact dust, - machine-cladding with Makrolon panels

- René Reiser Grafische Maschinen

- Höhenstrasse 5+7

- 75242 Neuhausen

- Deutschland

-

+49 (0) 7234-95310

+49 (0) 7234-953131 -

info@reiser-gm.de

www.reiser-gm.de

#2074-403 · Laser Cutting Machine

SEI Laser - GIOTTO CO2 3ax Compact 300 - - 2017 -

Technical details

- PTF GmbH

- Kreuzsteig 6

- 72479 Straßberg

- Deutschland

-

+49 7574 93 622 83

+49 7574 92 17 24 -

info@ptf-maschinen.de

www.ptf-maschinen.de

#2054-3188 · Laser Cutting Machine

Trumpf - TruLaser 3030 - 3kW Fiber - - 2017 -

Technical details

- PTF GmbH

- Kreuzsteig 6

- 72479 Straßberg

- Deutschland

-

+49 7574 93 622 83

+49 7574 92 17 24 -

info@ptf-maschinen.de

www.ptf-maschinen.de

#2054-3152 · Laser Cutting Machine

Bystronic - ByStar Fiber 3015 - 6 kW - - 2016 -

Technical details

- Broziat GmbH

- Vorwerker Str. 62a-64

- 23554 Lübeck

- Deutschland

-

+49 451 40 40 19

+49 451 40 73 93 -

info@Broziat.de

https://broziat.com

#2040-100531 · Laser Cutting Machine

TRUMPF - TruLaser Tube 7000 (T03) - - 2016 -

Technical details

The machine is checked by authorized checklist through specialists. 1. Option: Machine installation and manitnence at buyers location including function guarantyand operator training: Surcharge 42.000 € plus Transport and traveling costs Standard configuration Machine - Working range in X-axis for tubes 6500 mm - Outer circle diameter 204 mm - Flexible part removal station 3 m - NitroLine - FocusLine - Laser power control - Programmable cutting gas pressure - Programm re-entry - Automatic shut-down device - Work area lighting Laser - CO2-Laser TruFlow 2000 - Laser logbook function - Chiller Laser Cutting head - Lens cutting head with 155 mm focal length - ControlLine Controller - Sinumerik 840D - Teleservice via Internet Data Transfer - RJ45 network connection, USB-Interface Safety - CE marking - Multi-beam light barriers - Compact dust extraction unit 1500 Nm³/h - safety cabin with Macrolon panels

- Broziat GmbH

- Vorwerker Str. 62a-64

- 23554 Lübeck

- Deutschland

-

+49 451 40 40 19

+49 451 40 73 93 -

info@Broziat.de

https://broziat.com

#2040-100459 · Laser Cutting Machine

TRUMPF - TruLaser 5030 Fiber (L68) - - 2015 -

Technical details

The machine is in good condition. Workshop overhaul machine : Selling price 420 000€. Delivery date : +/- Oct-Nov 2023 Basic equipment Machine - Closed frame with integrated cabinet - Automatic longitudinal pallet changer - Axis drive by linear motor technology and torque motor - Laser beam transmission via fibre optics - Machine cooling unit (water-air) - Integrated electrical cabinets with interior lighting - Single electric switch for machine and laser - Longitudinal chip conveyor - Lighting of the working area - Laser positioning diode - Oil spraying device - PierceLine - FocusLine - NitroLine - PlasmaLine - Automatic nozzle cleaning - Transport and slinging device TRUMPF Laser - TruDisk 5001 solid state laser (5 kW) with fibre optic output - Fiber optic according to standard layout (laser source next to the machine) - Laser cooling unit (water-air) - Laser excitation via long-life diode module - Laser power control Laser cutting head - Universal cutting head with adaptive lens system - Single cutting head strategy - Cutting head protection window - Online control of the protective window - ControlLine Numerical control - CNC Sinumerik 840D SL - Integrated technology data (Laser table) - 17" colour touch screen - Automatic stop - Programmable cutting gas pressure - FastLine - FlyLine - AdjustLine - Teleservice via internet - Simple workshop programming - Fast reproduction - ContourLine - Microweld Data transmission - USB interface - RJ45 card for network connection Security - CE approvals - Safety light barriers - Compartmentalised suction device - Compact dust collector - Machine cabin with certified protective glass (right door) - Electric sunroof

- Broziat GmbH

- Vorwerker Str. 62a-64

- 23554 Lübeck

- Deutschland

-

+49 451 40 40 19

+49 451 40 73 93 -

info@Broziat.de

https://broziat.com

#2040-100502 · Laser Cutting Machine

TRUMPF - TruLaser 3030 Fiber (L49) - - 2015 -

Technical details

The machine is in good condition. 1. Instalacja maszyny wraz z gwarancj? rozruchow? - 11 000 Euro plus koszty transportu i delegacji serwisu 2. Remont maszyny wraz z 6 m gwarancj? na bezp?atn? dostaw? cz??ci zamiennych - 32 000 Euro TruLaser 30xx fiber (L49 / L75 / L50 / L51 / L66 / L81-X) Grundausstattung: Maschine - Geschlossener Maschinenrahmen - Automatischer Palettenwechsler in Längsrichtung - Torque-Antrieb in Kombination mit Linear-Direktantrieben - Geschlossene Strahlführung per Lichtleitkabel (LLK) - Maschinenkühlaggregat (Wasser-Luft) - Integrierte Schaltschränke mit Innenbeleuchtung - Stromversorgung TruDisk über die Maschine - Längsförderband - Arbeitsraumbeleuchtung - Positionslaserdiode - Öl Sprüheinrichtung - PierceLine - FocusLine - NitroLine - PlasmaLine - Automatische Düsenreinigung - Transport- und Montagevorrichtung TRUMPF Laser - Festkörperlaser TruDisk mit 1 LLK-Abgang - Laserkühlaggregat (Wasser-Luft) - Anregung über Pumpdioden - Laserleistungssteuerung Schneideinheit - Universal-Schneideinheit mit volladaptivem Linsensystem - Einschneidkopf-Strategie - Schutzglas gegen Linsenverschmutzung - Zustandsprüfung des Schutzglases - ControlLine: Höhenregelung und Blechaussenkantenerfassung Steuerung - Erweiterte Werkstattprogrammierung (TruTops über Netzwerkzugriff) - Schnelles Nachproduzieren - 17" Touch Farbbildschirm - Integrierte Technologiedaten - Abschaltautomatik - Programmierbare Schneidgas-/-druckanwahl - ContourLine - Microweld - FastLine - FlyLine - AdjustLine - Teleservice per Internet - Integrierter e-Shop Datenübertragung - USB-Schnittstelle - RJ-45 Netzwerkanschluss Sicherheit - CE-Kennzeichnung - Lichtschranken - Mehrkammerabsauganlage - Kompaktentstauber - Maschinenverkleidung mit zertifizierter Sichtscheibe (rechte Tür) - Rolldach

- Broziat GmbH

- Vorwerker Str. 62a-64

- 23554 Lübeck

- Deutschland

-

+49 451 40 40 19

+49 451 40 73 93 -

info@Broziat.de

https://broziat.com

#2040-100529 · Laser Cutting Machine

TRUMPF - TruLaser 5060 (L54) - - 2015 -

Technical details

The machine is in good condition. 1. Option: Machine installation, operator training at buyers location and partially refurbishing including function guaranty: Surcharge 18.000 € plus Transport and traveling costs 2. Option: Workshop refurbished machine including technical approval by manufacturers’ directive at our workshop. Machine installation, operator training and free delivery of spare parts for 6 months after installation. Surcharge: 44.500 € plus Transport and traveling costs. Delivery time +6 weeks. Basic equipment: machine - Closed frame with integrated Laser - Displacement unit for high-precision machining - Axis drive with linear motor technology and Gantry - Protected beam guidance - Single-head machining strategy - Cooling Package - Automatic pallet changer in the longitudinal direction - Chip conveyor and small parts in the cutting area - Lighting of the work area - Positioning laser diode - An oil vaporization - PierceLine - FocusLine - NitroLine - PlasmaLine laser trumpf - CO2 laser TruFlow - Radial turbine maintenance - Excitement radio frequency - Laser control TASC 3 - Laser power control - Laser Synopsis Laser cutting head - ControlLine CNC - CNC Sinumerik 840SL - Integrated information technology - laser array - TFT color display - Automatic stop - Pressure Programmable cutting gas - SprintLine - ContourLine - FastLine - Microweld - Flyline - Teleservices - Integrated E-shop - Programming Workshop Data Transmission - USB interface - Card RJ45 network connection security - Certifications CE - Optical Safety Sensors - Laser monitoring device - Compartmentalized suction device - Compact Dust Collector - Cabin machine panel Makrolon

- PTF GmbH

- Kreuzsteig 6

- 72479 Straßberg

- Deutschland

-

+49 7574 93 622 83

+49 7574 92 17 24 -

info@ptf-maschinen.de

www.ptf-maschinen.de

#2054-3120 · Laser Cutting Machine

Trumpf - TruLaser Tube 5000 FIBER 3kW ( - - 2015 -

Technical details

This reliable all-around machine replaces conventional, sepa- rate manufacturing operations such as sawing, drilling, milling and punching, and enables the ideal entry into the laser tube processing industry. It owes its high productivity to the perfectly coordinated operation of its components, from the laser unit and its beam guidance system to the clamping units and system control software as well as the tube and profile handling modules.

- Amann Werkzeugmaschinen GmbH

- Landshuter Straße 1

- 85716 Unterschleißheim

- Deutschland

-

(0049) 89 317754 0

(0049) 89 3174262 -

info@amann-wzm.de

www.amann-wzm.de

#1006-92350 · Laser Cutting Machine

AMADA - LCG3015 - - 2014 - AMNC-F

Technical details

- Gustav Schönberger GmbH

- Hünderstr. 14

- 74080 Heilbronn

- Deutschland

-

(0049)7131 46060

(0049)7131 460620 -

schoenberger@gsh-maschinen.de

www.gsh-maschinen.de

#1036-101160 · Laser Cutting Machine

BYSTRONIC - ByAutonom 3015 - - 2014 -

Technical details

with changing table (without automtic storage) ByVision Touchscreen and manual control unit Technische Daten / technical details: Laserleistung / laser capacity 6 kW Materialdicke Stahl / thickness of the material steel 25 mm Materialdicke Edelstahl / thickness of the stainless steel 20 Mm Materialdicke Alu / thickness of the material Aluminium 12 mm Blechgröße x,y / sheet size x,y 3000, 1500 mm Schneidbereich x,y,z, / cutting area x,y,z 3048, 1524, 80 mm Antriebsleistung / drive capacity 51 kW Gewicht ca. / weight ca. 15000 kg Technische Daten, Zubehör und Beschreibung der Maschine sind unverbindlich - Technical data, accessories and description of the machine are not binding.

- Broziat GmbH

- Vorwerker Str. 62a-64

- 23554 Lübeck

- Deutschland

-

+49 451 40 40 19

+49 451 40 73 93 -

info@Broziat.de

https://broziat.com

#2040-100496 · Laser Cutting Machine

TRUMPF - TruLaser 5060 (L19) - - 2014 -

Technical details

The machine is in good condition. 1. Option: Machine installation, operator training at buyers location and partially refurbishing including function guaranty: Surcharge 18.000 € plus Transport and traveling costs 2. Option: Workshop refurbished machine including technical approval by manufacturers’ directive at our workshop. Machine installation, operator training and free delivery of spare parts for 6 months after installation. Surcharge: 44.500 € plus Transport and traveling costs. Delivery time +6 weeks. Basic equipment: machine - Closed frame with integrated Laser - Displacement unit for high-precision machining - Axis drive with linear motor technology and Gantry - Protected beam guidance - Single-head machining strategy - Cooling Package - Automatic pallet changer in the longitudinal direction - Chip conveyor and small parts in the cutting area - Lighting of the work area - Positioning laser diode - An oil vaporization - PierceLine - FocusLine - NitroLine - PlasmaLine laser trumpf - CO2 laser TruFlow - Radial turbine maintenance - Excitement radio frequency - Laser control TASC 3 - Laser power control - Laser Synopsis Laser cutting head - ControlLine CNC - CNC Sinumerik 840D - Integrated information technology - laser array - TFT color display - Automatic stop - Pressure Programmable cutting gas - SprintLine - ContourLine - FastLine - Microweld - Flyline - Teleservices - Integrated E-shop - Programming Workshop Data Transmission - USB interface - Card RJ45 network connection security - Certifications CE - Optical Safety Sensors - Laser monitoring device - Compartmentalized suction device - Compact Dust Collector - Cabin machine panel Makrolon

- Broziat GmbH

- Vorwerker Str. 62a-64

- 23554 Lübeck

- Deutschland

-

+49 451 40 40 19

+49 451 40 73 93 -

info@Broziat.de

https://broziat.com

#2040-100505 · Laser Cutting Machine

TRUMPF - TruLaser 5030 Fiber (L56) - - 2014 -

Technical details

The machine is in good condition. 1. Instalacja maszyny wraz z gwarancj? rozruchow? - 11 000 Euro plus koszty transportu i delegacji serwisu 2. Remont maszyny wraz z 6 m gwarancj? na bezp?atn? dostaw? cz??ci zamiennych - 32 000 Euro (TruLaser 50xx fiber (L41 / L56 / L68 / L47 / L57 / L69 / L76xx Grundausstattung MASCHINE: - Geschlossener Maschinenrahmen - Automatischer Palettenwechsler in Längsrichtung - Torque-Antrieb in Kombination mit Linear-Direktantrieben - Geschlossene Strahlführung per Lichtleitkabel (LLK) - Maschinenkühlaggregat (Wasser-Luft) - Integrierte Schaltschränke mit Innenbeleuchtung - Stromversorgung TruDisk über die Maschine - Längsförderband - Arbeitsraumbeleuchtung - Positionslaserdiode - Öl Sprüheinrichtung - PierceLine - FocusLine - NitroLine - PlasmaLine - Automatische Düsenreinigung TRUMPF Laser - Festkörperlaser TruDisk mit 1 LLK-Abgang - LLK gemäss Standardlayout (Laser direkt neben Maschine) - Laserkühlaggregat (Wasser-Luft) - Anregung über Pumpdioden - Laserleistungssteuerung SCHNEIDEINHEIT - Universal-Schneideinheit mit volladaptivem Linsensystem - Einschneidkopf-Strategie - Schutzglas gegen Linsenverschmutzung - Zustandsprüfung des Schutzglases - ControlLine: Höhenregelung und Blechaussenkantenerfassung STEUERUNG - Erweiterte Werkstattprogrammierung (TruTops über Netzwerkzugriff) - Schnelles Nachproduzieren - 17" Touch Farbbildschirm - Integrierte Technologiedaten - Abschaltautomatik - Programmierbare Schneidgas-/-druckanwahl - ContourLine - Microweld - FastLine - FlyLine - AdjustLine - Teleservice per Internet - Integrierter e-Shop - USB-Schnittstelle - RJ-45 Netzwerkanschluss SICHERHEIT - CE-Kennzeichnung - Lichtschranken - Mehrkammerabsauganlage - Kompaktentstauber - Maschinenverkleidung mit zertifizierter Sichtscheibe (rechte Tür) - Elektrisches Rolldach

- Matthias Ehlers Werkzeugmaschinen

- Nikolaus-Otto-Straße 19 + 21

- 22946 Trittau

- Deutschland

-

+49 (0)4154 - 986 99 12

+49 (0)4154 - 986 99 14 -

anfrage@ehlers-wzm.de

www.ehlers-wzm.de

#2033-2024034 · Laser Cutting Machine

BYSTRONIC - Bystar 3015 - - 2013 - Bystronic

Technical details

In our opinion, the machine is in very good condition used condition. Technical details: - Maximum workpiece thickness: - Mild steel: 25 mm - Aluminum: 15mm Accesories: - Bylaser 6000 - Cooling system - Byloader 3015 loading system - Safety barriers from Sick ***Accessories, tools and clamping devices shown are only included in the scope of delivery if this is noted in the additional information.*** ***Changes and errors in the technical data and information as well Subject to prior sale!***

- Bästlein

- Augsburger Str. 56

- 89312 Günzburg

- Deutschland

-

+49 (0) 8221 93037-0

+49 (0) 8221 93037-29 -

info@baestlein.com

www.baestlein.com

#1123-4051623 · Laser Cutting Machine

TRUMPF - TruLaser 5030 FIBER (L56)- 5kW - - 2013 -

Technical details

- Broziat GmbH

- Vorwerker Str. 62a-64

- 23554 Lübeck

- Deutschland

-

+49 451 40 40 19

+49 451 40 73 93 -

info@Broziat.de

https://broziat.com

#2040-100479 · Laser Cutting Machine

TRUMPF - TruLaser 3030 (L20) - - 2013 -

Technical details

The machine is overhauled in our workshop and will be sold with 6 month parts guaranty.

- Bästlein

- Augsburger Str. 56

- 89312 Günzburg

- Deutschland

-

+49 (0) 8221 93037-0

+49 (0) 8221 93037-29 -

info@baestlein.com

www.baestlein.com

#1123-4051132 · Laser Cutting Machine

BYSTRONIC - ByAutonom 3015 - - 2013 -

Technical details

Accessories/equipment: - CO2 laser source ByLaser 4400 - Cutting heads 5", 7,5" - Power On: 10.981 h (March 2019) - Laser On: 3.927 h (March 2019) Youtube-Video-Links: https://www.youtube.com/watch?v=WUdeITk5QRg&feature=youtu.be https://www.youtube.com/watch?v=mtDk8b9_L0U&feature=youtu.be

- PTF GmbH

- Kreuzsteig 6

- 72479 Straßberg

- Deutschland

-

+49 7574 93 622 83

+49 7574 92 17 24 -

info@ptf-maschinen.de

www.ptf-maschinen.de

#2054-2805 · Laser Cutting Machine

Bystronic - ByAutonom 3015 - - 2013 -

Technical details

Laser cutting is a precision process with a wide variety of applications on a large number of materials. From engraving to large scale cutting laser cutting is the preferred method for industrial manufacturers and hobby metal workers alike. With the level of accuracy and precision offered by a laser cutting machine it's easy to see why this method has steadily grown in popularity over time. If you're in the market for a laser cutting machine check out LagerMaschinen for a plethora of options.

Discover the advantages of laser cuttingLaser cutting has a large number of advantages to offer. The compact size of the laser beam provides extreme precision and control resulting in extremely clean edges. With the rapid advancements in technology you can find a laser cutting machine able to penetrate even dense thicker materials a job which previously required a lot more man-hours. With the wide rage of machinery available finding a used laser cutting machine at LagerMaschinen is easy.

LagerMaschinen: the best for your budget and businessBuying used machinery is a practical and affordable solution to the many woes of outfitting a business or personal workspace. Smart investors know you can get the most for your time and money by shopping online for used equipment. LagerMaschinen offers users an easy-to-use interface allowing you to shop based on need location or price. Whether you need a laser cutting machine or any other type of industrial equipment make LagerMaschinen your first and last shopping stop.

TOP Manufacturer:

TRUMPF - HESSE BY DURMA - BYSTRONIC - AMADA - ERMAK - DURMA - ROFIN - MESSER - TRUMPF 3 D - SEI LASER -