Machine data

Document

Nessun altro documento disponibileTechnical details

| pressure | 200 t |

| Control | Infinitron |

| work height max. | 1104 mm |

| throat | 250 mm |

| table width | 160 mm |

| pre-running speed | 2,67 mm/min |

| work speed | 0,001- 0,01 m/min |

| return speed | 2,67 mm/min |

| tank capacity | 550 l |

| total power requirement | 28 kW |

| weight of the machine ca. | 16,6 t |

| dimensions of the machine ca. | 4,4x2,7x3,4 m |

Videos

Additional information

Hydro cushion MHK 1-30

Three-point die holder DH 1-30

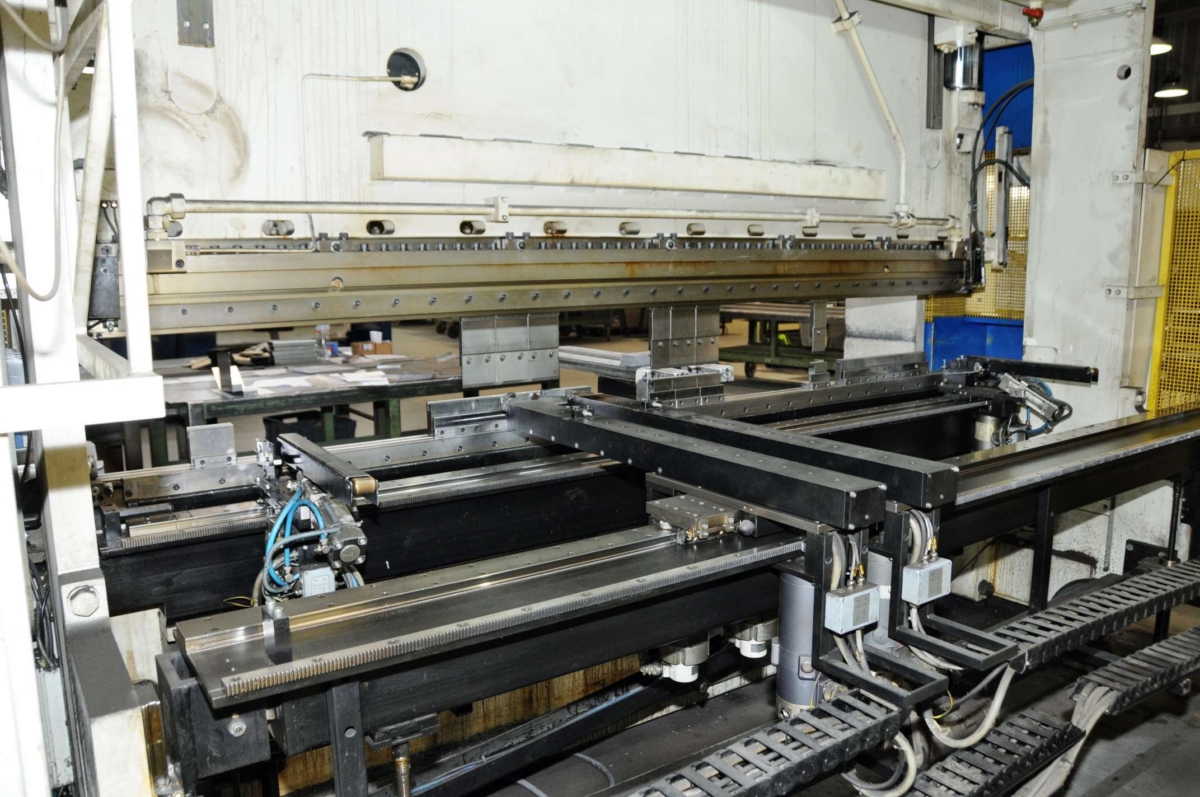

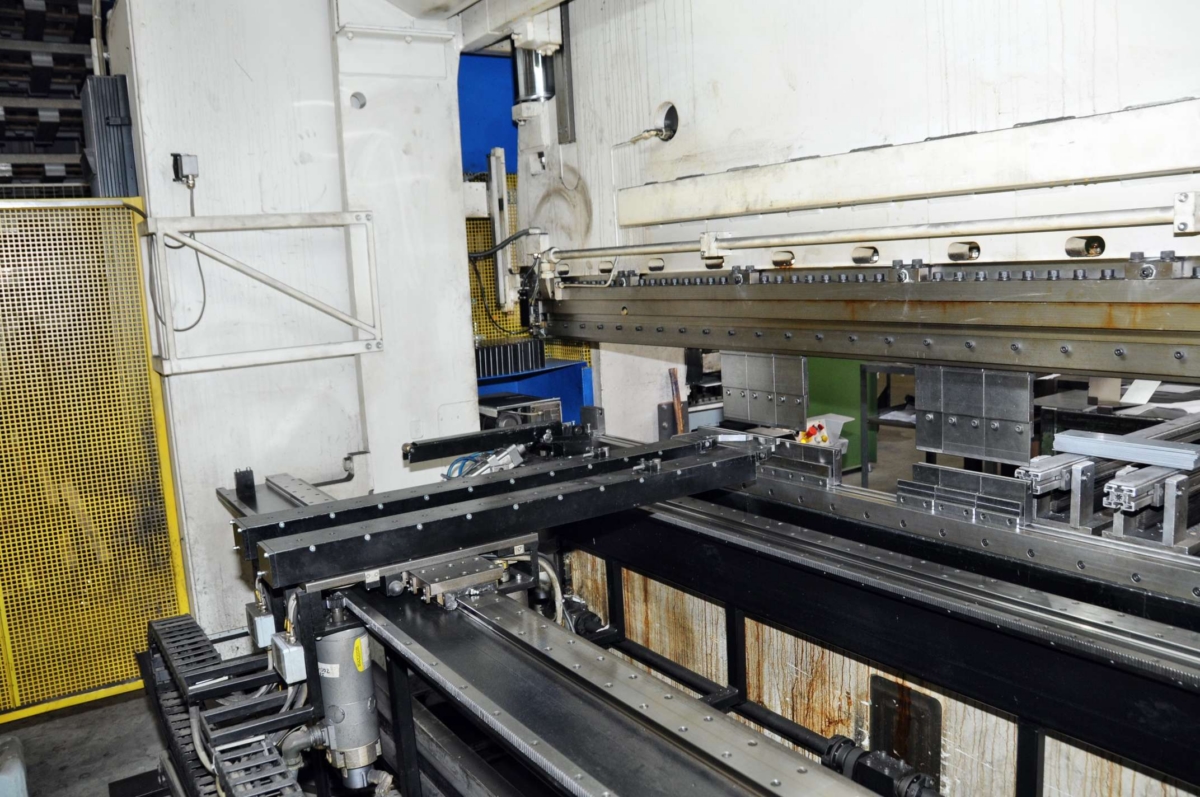

Stop system A2 with a travel range of 600 mm

Adjustment of the stop slide along the stop bar by separate

controlled Z-axes

Sheet metal support system H 2

Adjustment of the individual sheet metal support brackets by separately

controlled W-axes

Bracket SK 10 with lifting aid 0-45 ° with linear guide

technical description

Slim stand principle with 500 mm free passage. The stands are provided with

swivel bearings on which the table is placed. On the one hand, the cylinders

are screwed between the side stands and clearly positioned by means of wedges.

On the other hand, the cylinders are bolted to the support at the front and

rear, resulting in a stabilizing frame construction.

The hydraulic tank is screwed between the side stands and contains all the

block hydraulics for controlling the individual machine elements such as the

tappet drive, tool clamping, die slide device, etc.

The movement of the plunger is controlled by electronically controlled

proportional valves, a gray scale being provided on each side of the plunger

for precise measurement of the position. Both the parallel position and the

exact lower action point position are controlled by the CNC control via the

valves mentioned, with a stopping accuracy of 0 / - 0.01 mm being maintained at

the bottom dead centre. The frame suspension (frame on suspension) is

compensated on both sides by mounting the gray scales on separate supports that

are attached directly to the table.

The ram is rapidly advanced by ancestors under the influence of its own weight,

whereby the press cylinders are supplied with oil by means of large suction

valves. After the switchover point from the forward speed to the working speed

has been reached, the plungers are supplied with oil from the main pump via the

proportional valves.

The steel press cylinders are double-acting, with the piston rods being

connected to the ram by cambered supports and elastic intermediate links. A

safety control independent of the electronics registers the parallel position

of the ram and switches the machine off immediately if, due to a fault in the

electronics of the ram, it does not remain in the parallel position. Otherwise,

the dangerous functions of the hydraulics are automatically checked and secured

in accordance with the latest accident prevention regulations.

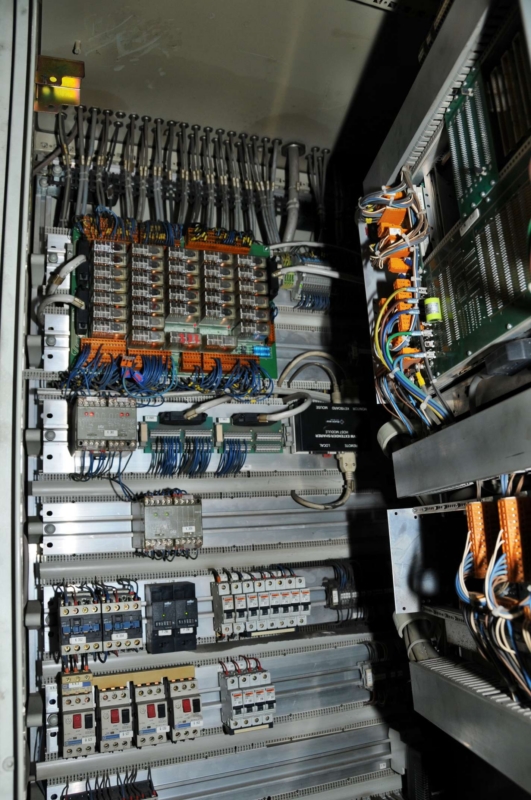

The electrical cabinet on the right side of the machine essentially contains

the power section, the computer section and the safety section. The connections

from the electrical box to the mechanical part are made using plug connections.

The machine and accessories comply with the currently applicable provisions of

Directive 89/392 / EEC (machines) amended by Directives 91/368 / EEC and 93/44 /

EEC.

The machine price includes the required side and rear protective grilles and

two-hand operation with a safety stop.

Three-point die holder DH 1-30

Stop system A2 with a travel range of 600 mm

Adjustment of the stop slide along the stop bar by separate

controlled Z-axes

Sheet metal support system H 2

Adjustment of the individual sheet metal support brackets by separately

controlled W-axes

Bracket SK 10 with lifting aid 0-45 ° with linear guide

technical description

Slim stand principle with 500 mm free passage. The stands are provided with

swivel bearings on which the table is placed. On the one hand, the cylinders

are screwed between the side stands and clearly positioned by means of wedges.

On the other hand, the cylinders are bolted to the support at the front and

rear, resulting in a stabilizing frame construction.

The hydraulic tank is screwed between the side stands and contains all the

block hydraulics for controlling the individual machine elements such as the

tappet drive, tool clamping, die slide device, etc.

The movement of the plunger is controlled by electronically controlled

proportional valves, a gray scale being provided on each side of the plunger

for precise measurement of the position. Both the parallel position and the

exact lower action point position are controlled by the CNC control via the

valves mentioned, with a stopping accuracy of 0 / - 0.01 mm being maintained at

the bottom dead centre. The frame suspension (frame on suspension) is

compensated on both sides by mounting the gray scales on separate supports that

are attached directly to the table.

The ram is rapidly advanced by ancestors under the influence of its own weight,

whereby the press cylinders are supplied with oil by means of large suction

valves. After the switchover point from the forward speed to the working speed

has been reached, the plungers are supplied with oil from the main pump via the

proportional valves.

The steel press cylinders are double-acting, with the piston rods being

connected to the ram by cambered supports and elastic intermediate links. A

safety control independent of the electronics registers the parallel position

of the ram and switches the machine off immediately if, due to a fault in the

electronics of the ram, it does not remain in the parallel position. Otherwise,

the dangerous functions of the hydraulics are automatically checked and secured

in accordance with the latest accident prevention regulations.

The electrical cabinet on the right side of the machine essentially contains

the power section, the computer section and the safety section. The connections

from the electrical box to the mechanical part are made using plug connections.

The machine and accessories comply with the currently applicable provisions of

Directive 89/392 / EEC (machines) amended by Directives 91/368 / EEC and 93/44 /

EEC.

The machine price includes the required side and rear protective grilles and

two-hand operation with a safety stop.

On this page you will find a an offer on a used Hydr. pressbrake of type BM 200-3100 of the company HÄMMERLE with year of construction 1997 and with stock no.: 2069-7839. The machine is manufactured by the company MWB GmbH & CO. KG from 09456 Annaberg-Buchholz offered. The delivery time / delivery status for this machine is: immediately For more information, please refer to the details listed.

Documenti e video

Nessun altro documento disponibile