Travelling column milling machine

Machinelist: Travelling column milling machine

Lateral Milling Machine

- Franz Hoppe GmbH

- Im Hasseldamm 1

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 21 61 / 67 79 20

+49 (0) 21 61 / 67 34 56 -

mail@hoppe-maschinen.de

www.hoppe-maschinen.de

#1015-456747 · Lateral Milling Machine

JOBS - JOMACH 159 - - 2005 - SIEMENS-SINUMERK 840 D

Technical details

* spindle on appr. 13,721 h * CNC-control in 5 axis by SIEMENS SINUMERIK 840 D * CNC universal milling head A-axis = +-90° - C-axis = 400° (+200/-200°) * 52-fold tool changer

Travelling column milling machine

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-94900 · Travelling column milling machine

KRAFT - TCM-266/366/466/666/866 - - Fabrikneu - Heidenhain 620

Technical details

Traveling Column 5 Axis Machining Center

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-94901 · Travelling column milling machine

KRAFT - Duplex B+C-Achse - - Fabrikneu - Heidenhain TNC- 620

Technical details

Traveling Column 5 Axis Machining Center

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-98111 · Travelling column milling machine

KRAFT - Ulisse - - Fabrikneu -

Technical details

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

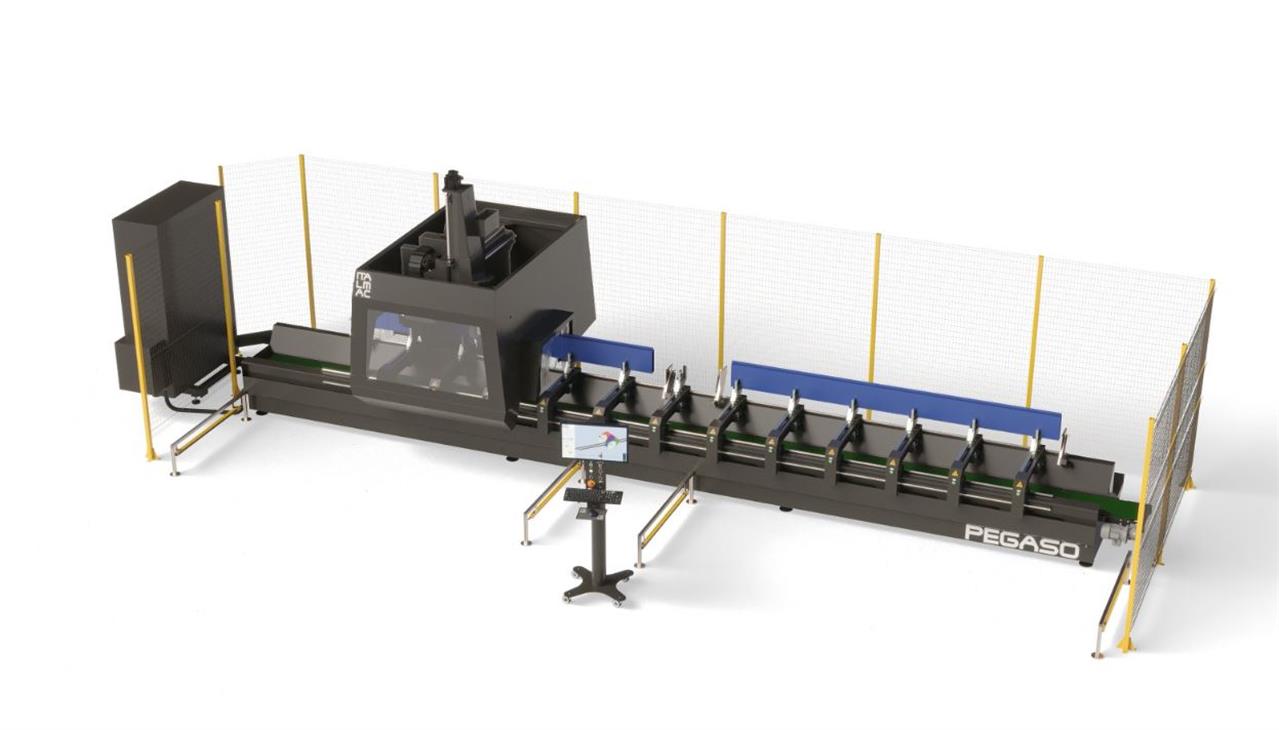

#4019-98112 · Travelling column milling machine

ITALMACH - Pegaso - - Fabrikneu -

Technical details

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20250 · Travelling column milling machine

AXA - VHC 3 XTS - - 2018 - Heidenhain TNC 640

Technical details

Travelling column machining centre - CNC Control Heidenhain TNC 640 - Electronic handwheel with 2 m spiral cable - Pendel operation - Extension of stroke Y to 1000 mm and Z to 950 mm, table width 1000 mm OM-- Extension of basic tool magazine from 22 to 36 places - Infinitely adjustable NC-tilting head in 1 axis, freely interpolatable - Increased power of main drive - Speed range 30-12.000 rpm - Internal cooling 20 bar - Cooling through the spindle centre by means ofpressurised air flow - Preparation for chip conveyor, incl. wiring - AXA RTA 5TF-1250 rotary table -- Integration of rotary table into fixed table with curvature adjustment - 2 pcs of manual rinsing gun for cooling water cleaning - workpiece probe Blum TC60, radiobeam - Tool cable probe Blum ZX Speed - Preparation of the cabin for extraction ofmist from machining

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20249 · Travelling column milling machine

IBARMIA - ZV 58 / 7000 - - 2018 - Heidenhain TNC 640

Technical details

- CNC Control Heidenhain TNC 640 - ATC 60-fold (ISO 50) - Coolant with paper band filter - Tool Probe Renishaw - Spindle Hours: 6500h

- Kraft Werkzeugmaschinen GmbH

- Wilhelmstraße 20

- 64589 Stockstadt

- Deutschland

-

+49 (0) 6158/9999975

-

nr@kraft-werkzeugmaschinen.de

www.kraft-werkzeugmaschinen.de

#4019-100542 · Travelling column milling machine

FPT - TESSEN - - 2018 - Heidenhain 530

Technical details

Traveling Column 5 Axis Machining Center

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-15921 · Travelling column milling machine

PARPAS - SHARK One - - 2016 - HEIDENHAIN iTNC 530 HSCI

Technical details

GEquipment • Machine bed, column and vertical saddle as welded steel construction, annealed with low tension • Milling slider as welded steel construction • Orthogonal milling head TUB-E92 with motor spindle, C- and A-axis drive via torque motors • Oil cooling unit for cooling the milling head • CNC thermal compensation • Spindle drive 29 kW • Spindle speed max. 18.000 min-1 • Axle drives by means of precision ball screws and digital servo motors • Touch probe system manufacturer BLUM, TC 63-30 with radio transmission and automatic measuring cycles • Milling head Measurement “Kinematics Opt” • Laser tool presetter BLUM - NT version mounted on machine table • CNC control HEIDENHAIN iTNC 530 HSCI incl. digital drive technology • Portable electronic handwheel HEIDENHAIN HR 520 with 3 m spiral cable • swivelling control panel for machine operation in front of the machine • Automatic tool changer with 30 magazine places, change position vertical • Coolant system with external shower rim and IKZ through the spindle • 1 chip conveyor in the working area, ejection right • Pretensioned linear guides in all axes • Precision ball screws in Y- and Z-axis • X-axis drive via gear rack and master/slave drive • Hydraulic weight compensation in the vertical axis • Bellows cover of the X-axis • Milling slide above and below in the vertical axis with bellows covers with attached stainless steel lamellas closed • Work area enclosure closed on all sides. Back side of the work area with bellows cover with attached stainless steel lamellas closed. The manual sliding doors on the front of the machine can be opened and closed over the entire length of the table. Safety fencing for the back machine area with two secured access doors.

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9167 · Travelling column milling machine

CHIRON - Mill FX 800 - - 2015 - TNC 640 Millturn Heidenhain

Technical details

CNC - Travelling Column Milling Machine CHIRON - Mill FX 800

- STEINHAND GmbH

- Am Stahlwerk 15

- 45527 Hattingen

- Deutschland

-

+49 (0) 2324 / 977 26 - 01

+49 (0) 2324 / 977 26 - 99 -

info@steinhand.de

www.steinhand.de

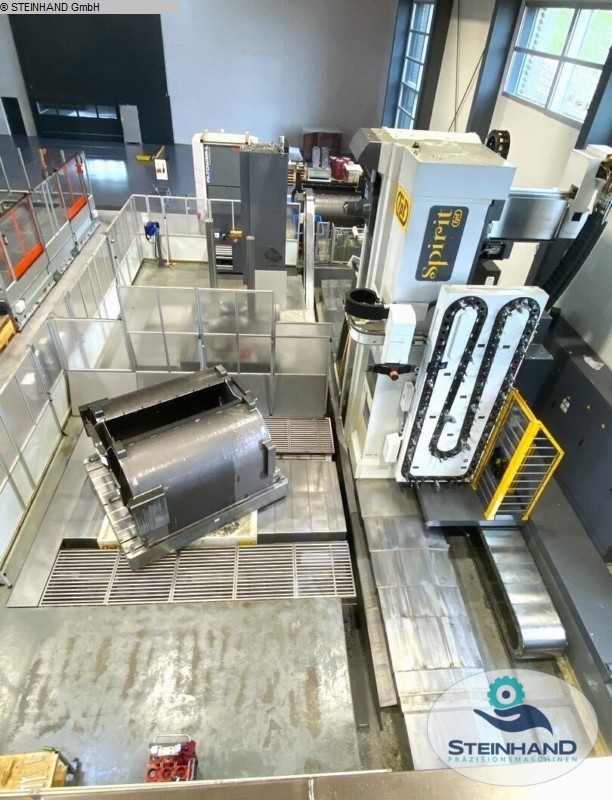

#2026-1620 · Travelling column milling machine

FPT - SPIRIT 140 - - 2014 - Siemens 840 Dsl

Technical details

Milling machine | SPIRIT 140 - 2014 equipped with two HYDROSTATIC rotary boring tables (TRT30). The machine has only approx. 9.900 H working hours. Equipment: - Hydrostatic guideways - Cooling system - Handwheel with radio transmission (HBG 800-DP) - ITC (40 bar) - Tool changer (80 pcs. | ISO50) - Magazine for changing the milling heads with 3 places - Infinitely positionable universal head - Horizontal spindle extension (long version) - chip conveyor - Laser probe with software for tool measurement and breakage control - Radio measuring probe (M&H) - Pendulum processing with partition The machine is in very good condition. For additional equipment information please refer to the original order confirmation which is included in the offer of this machine. A machine video from the production plant will be shared on request. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - #Tags: SPIRIT-140 | SPIRIT140"

- Intermach BV

- lange voor 71

- 8316BC Marknesse

- Niederlande

-

+31 (0)653235637

-

info@intermach.nl

www.intermach.nl

#2050-1110070 · Travelling column milling machine

CORREA/ANAYAK - HVM80 - - 2014 - Heidenhain Itnc 530

Technical details

Brand: CORREA/ANAYAK Typ: HVM 80 Build in : 2014 travel X/Y/Z 8,000 x 1,500 x 2,500 mm, Spindel : max. 6000 Rpm Spindelpower 28 Kw as extra :high frequency spindle, type HFS IMT Mold, max. 26,000 rpm, max. 11 kW, table dim. (floorplates)8,000 x 2,500 x 300 mm, T-slots 22 H12, distance T- slots 250 mm, table load max. 15,000 kg/m², distance spindle - column max. 1,675 mm, feeds X/Y/Z max. 30,000 mm/min, Total power 96 Kw machine weight 55,000 kg, column 12,000 kg, platen 16,000 kg, 2x CNC screen control, make Heidenhain, type CNC I 530, autom. tool changer, chain type, max. 60 tools, tool holder SK50, tool weight max. 25 kg, tool L max. 400 mm, radio manual control panel, make Heidenhain, type HR-550, telediagnosis system, autom. universal milling head, external cooling, max. 5 bar, self-cleaning filter, tank, volume 600 l, tool outside air cooling, tool inside air cooling, hinged belt chip conveyor, protective housing, tool measuring probe M&H 20.41, control cabinet, ser. No. 218/14,

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03754 · Travelling column milling machine

SORALUCE - Dano Batgro FR-30000 - - 2013 - Heidenhain

Technical details

The tech. Data are manufacturer or operator information and therefore non- binding. We reserve the right to prior sale; Our terms and conditions of sale apply exclusively.About usMore than 400 of our own machines in the warehouseMore than 12,000 m² of storage space, crane capacity 70 tMore than 1000 items Accessories for your workshopYou want to sell machines, production lines or your company,then contact us.

- Harry Vraets Machinery B.V.

- Gezellenstraat 2

- 3861RD Nijkerk

- Niederlande

-

+31 (0)332452145

-

info@vraetsmachinery.com

www.vraetsmachinery.com

#2039-12953L · Travelling column milling machine

SORALUCE - Dano Batgro FR-30000 - - 2013 - Heidenhain TNC 530i

Technical details

Woeking hours: 9332 Machine number: 5619 Chipconveyor: 2x Angle plates: 4x Box table

- Intermach BV

- lange voor 71

- 8316BC Marknesse

- Niederlande

-

+31 (0)653235637

-

info@intermach.nl

www.intermach.nl

#2050-1110049 · Travelling column milling machine

FPT - Spirit 130 - - 2012 - Heidenhain Itnc 530

Technical details

Stocknumber 1110049 Type of machine CNC floortype milling machine Make FPT Type Spirit 130 Build in 2012 Type of control HEIDENHAIN TNC Itnc 530 X-stroke (mm) 14.000 Y-stroke (mm) 1.500 Z-stroke (mm) 3.000 Speeds (Rpm) max. 4.000 Admission in spindlehead Iso 50 Rapid feeds max 25.000 mm/min Additional information Program run 9655 hour

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9172 · Travelling column milling machine

DECKEL MAHO - DMF 260 New Design - - 2010 - iTNC 530 Heidenhain

Technical details

CNC - Travel Column Milling Machine DECKEL MAHO - DMF 260 New Design - NC dividing head (A-axis) - Operating hours: 18.709h spindle run - overhauld spindle installed (Dec 2023) - Z-axis weight compensation changed (Feb 2023) - Production package - Option: tool clamping for tightening bolts - WITHOUT vices!

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-668 · Travelling column milling machine

SORALUCE - FL 5000 - - 2009 -

Technical details

- Glaub Werkzeugmaschinen GmbH

- Industriestraße 36

- 74194 Neuenstadt am Kocher

- Deutschland

-

+49 (0) 7139 9366 744

+49 (0) 7139 9365 794 -

service@gwg-maschinen.com

www.gwg-maschinen.com

#2029-1182 · Travelling column milling machine

DMG - DMF 250 Linear - - 2009 - Heidenhain iTNC 530

Technical details

- Table size: 3100 x 900 mm - 30-fold tool changer - Tool holder: SK50 - spindle speed: max. 10.000 rpm - Chip conveyor make DMG - Collision monitoring system make Brankamp - Measuring probe M+H - Partition wall for pendulum machining - incl. 50 tool holders SK50

- MS Maschinenhandel GmbH

- Unterdorf 34

- 6532 Ladis

- Österreich

-

+43 547221907

+43 54722190722 -

info@ms-maschinen.at

www.ms-maschinen.at

#2034-93 · Travelling column milling machine

SORALUCE - FP 6000 - - 2009 - HEIDENHAIN iTNC 530

Technical details

The SORALUCE FP6000 is in very good condition. accessories as option: # clamping angle: 5'000.-€ # Clamping cube: 2'000.-€ # Div. tools & workbench: 2'000.-€ Description: - CNC control: HEIDENHAIN ITNC 530 Orthogonal milling head: - Tool holder: ISO 50, DIN69871 AD - Automatic tool clamping: Clamping force 20,000 N - Indexing accuracy / repeatability: ± 3 sec. == ± 0.002 mm - Tightening bolt: DIN 69872 form A - Number of swivel positions: 1 x 1 ° milling head ( 360 positions rear plane, 270 positions front plane) 270 positions front plane) - Diameter spindle bearing: 90 - Sealing air: 0,7 bar Main drive: - Drive type: three-phase motor - Drive power: 100 % ED 32 kW spindle: - Spindle speed: 20 - 4000 rpm - Full power from: 340 rpm - Torque at 32 kW/S1: 910 Nm - Speed control: 2 ranges infinitely variable via star/delta connection Rapid traverse: max. 35000 mm/min

- Goedicke Werkzeugmaschinenhandels GmbH

- Heinz-Nixdorf-Str. 2

- 74172 Neckarsulm

- Deutschland

-

+49-(0) 7132–999 360

+49-(0) 7132–999 3690 -

info@goedicke.com

www.goedicke.com

#1048-746688 · Travelling column milling machine

SORALUCE - FP 6000 - - 2009 - HEIDENHAIN iTNC 530

Technical details

Technical description : Traveling column milling machine with Heidenhain TNC530 control, coolant system, chip conveyor and STOLLE floor plate area 7000 mm length and by 2000 mm width (valued at Euro 20.000 is included). - NOTE: The clamping table, the clamping angle, are NOT included in the scope of delivery. Those optionals can be purchased separately at following EXW ex works prices ANGLE PLATE Euro 5.000,-- PER UNIT CUBE FOR CLAMPING EURO 2.000,--

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19294 · Travelling column milling machine

JUARISTI - MX 3 - - 2007 - Siemens 840D

Technical details

Travelling column milling machine with - control Siemens 840D - autom. Bi-rotativ milling head, 1x1°, 5000 U/min - tool changer 2x 40-fold (ISO 50) - chip conveyor - 2 Rotary Tables (dia 1500mm) - Renishaw RMP 60 - Laser Sensopart - Coolant (Through Spindle and External)

- Stiens Werkzeugmaschinen GmbH

- Mittelweg 92

- 59302 Oelde

- Deutschland

-

+49 252283490

(0049) - 2522 - 8349-20 -

info@stiens.de

www.stiens.de

#1039-9191 · Travelling column milling machine

MATEC - 50 HV-3000 - - 2006 - Sinumerik 840 D Siemens

Technical details

CNC - Travel Column Milling Machine MATEC - 50 HV-3000 - 5 Axis - Swivable-Milling-Head - NC-Rotary Table in Fixed Table - Separating-Wall / Double-Place-System - incl. Spare-Spindle Kessler

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20036 · Travelling column milling machine

MECOF - Unica CS-50 CNC - - 2005 - Selca S 3045L

Technical details

- CNC control Selca S 3045L - Tool changer 41-fold (ISO 50) - autom. BiRotativ milling head - Coolant & filter system - chip conveyor

- Jansen Machinehandel BV

- Bredaseweg 210

- 4873 LA Etten-leur

- Nederland

-

+31 (0) 76 5015750

-

info@jansenmachinehandel.nl

www.jansenmachinehandel.nl

#2049-F524 · Travelling column milling machine

Correa - Rapid 50 - - 2004 -

Technical details

5-axis machine

A travelling column milling machine is a crucial tool in the field of industrial metalworking and machining. Milling machines differentiate themselves from metal cutting processes by utilizing a moving spindle or cutting surface. The workpiece remains stationary while the spindle moves on 2 - 3 axes performing both basic and intricate cuts. If you're in the market for a travelling column milling machine check out the wide variety of used equipment available at LagerMaschinen.

Find the best metal cutting products at LagerMaschinenMilling machines are extremely versatile in the finishing processes of metals and other solid materials. With such a wide array of machines available in this day and age finding the right travelling column milling machine for you may seem daunting. But it doesn't have to be. By browsing LagerMaschinen's user-friendly site you can search for your next travelling column milling machine based on your location your price range or a specific model. Buying used machinery online saves you not only time but money!

Buying used machinery online is a quick and easy processBuying used machinery doesn't mean you have to sacrifice quality for the sake of your budget. You can find a lightly used machine like a travelling column milling machine based on the unique needs of your business. If you are concert with transport costs search by location. If money is the main issue search by price. No matter what your priorities are you can find a travelling column milling machine or any other equipment easily at LagerMaschinen.

TOP Manufacturer:

ZAYER - SORALUCE - ANAYAK - BUTLER-NEWALL - FPT - MATEC - KRAFT - BUTLER-ELGAMILL - AXA - COLGAR -